The world´s No 1 Trade Fair for Plastics and Rubber

Visit us at Munich Germany !

Hall / Booth: B6 114

From May 13th 2024 to May 17th 2024

Visit us at Munich Germany !

Hall / Booth: B6 114

From May 13th 2024 to May 17th 2024

Visit us at Amsterdam!

Booth: J50

From: June, 19th 2024 to June, 20th 2024

Visit us at Dortmund!

Hall / Booth: 7-S31

From: 9. October 2024 to 10. October 2024

Visit us at Friedrichshafen Germany !

Hall / Booth: A6-6201

From October, 15th 2024 to October, 19th 2024

Visit us at Mumbai!

Booth: P612

From: December, 4th 2024 to December, 6th 2024

Visit us at Amsterdam!

Booth:

From: May, 10th 2023 to May, 11th 2023

Visit us at Barcelona

From: May 30.2023 To June 02.2023

Hall: Booth:

Visit us at Milan!

Hall: 15 Booth: A147

From: September, 5th 2023 to September, 8th 2023

Visit us at Friedrichshafen Germany !

Hall / Booth: A6-6201

From October, 19th 2023 to October, 21th 2023

Visit us at Kielce / Poland

Booth:

From: May 24th 2022 to May 27th 2022

Visit us at Munich Germany !

Hall / Booth: 2.1 B19

From Mai 30th 2022 to June 3rd 2022

Visit us at Amsterdam!

Booth: J 31

From: June, 22th 2022 to June, 22th 2022

Visit us at Düsseldorf / Germany

Hall: 9 / Stand: 9D19

From: October, 19.2022 to October, 26.2022

Visit us in Moscow

Booth: 2/22B31

From: January 28th 2020 to January 31th 2020

Visit us at Shanghai

Hall / Booth: 2.1 B19

From: April 21th 2020 to April 24th 2020

Visit us at Kielce / Poland

Booth:

From: May 19th 2020 to May 22th 2020

Visit us at Munich Germany !

Hall / Booth: 2.1 B19

From September 7th 2020 to September 11th 2020

Visit us at Friedrichshafen Germany !

Hall / Booth: A6-6201

From Oktober, 13th 2020 to Oktober, 17th 2020

Visit us at Amsterdam!

Booth: C 9

From: October, 27th 2020 to October, 28th 2020

Visit us in Moscow

Booth: 2/22B31

From: January 28th 2019 to February 1st 2019

Visit us at Lahore

Hall: 2 Booth: 2-175

From: March 22th 2019 to March 24th 2019

Visit us at Amsterdam!

Booth: C9

Von: April, 10th 2019 to April, 11 2019

Visit us at Kielce / poland

Booth:

From: May 28th 2019 to May 31th 2019

Visit us at Lagos!

Booth:

From: September 17th. 2019 to September 19th 2019

Visit us in Lahore – Pakistan!

Hall: 1

Booth: B-137 & 138

From: November, 4th 2019 to November, 19th 2019

Visit us at Düsseldorf / Germany

Hall: 9 / Stand: 9D37

From: October, 16.2019 to October, 23.2019

Visit us at Wiesbaden – Germany

From: November 27th 2019 to November 28th 2019

Visit us in Moscow

Booth: 2/2B31

From: January 23th 2018 to January 26th 2018

Visit us at Gujarat

Booth: 8C14

From: February, 07th 2018 to February, 12th 2018

Visit us at Amsterdam!

Booth: C7

From: April, 24th 2018 to April, 25th 2018

Visit us at Shanghai

Hall / Booth: 2K46

From: April 24th 2018 to April 27th 2018

Visit us at Munich Germany !

Hall: B6

Booth: 114

From May 14th 2018 to May 18th 2018

Visit us at Friedrichshafen Germany !

Hall: A6

Booth: 6201

From Oktober, 16th 2018 to Oktober, 20th 2018

Visit us at Alger / Algeria

Hall / Booth: 1E.21

From March 11th 2018 to March 13th 2018

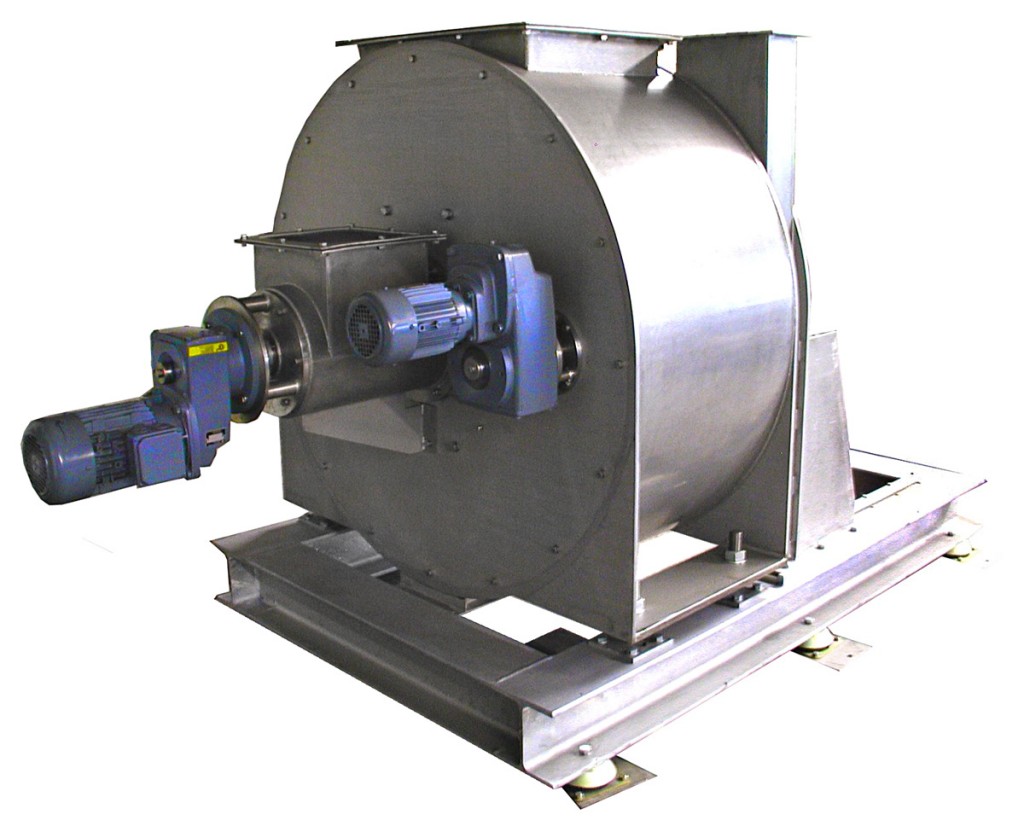

The well-proven Pulverizer ZM 800 has now been renewed: In future the ZM 800 will convince its users with clever optimizations. A new machinery construction has taken place and modifications were realized which offer further operation advantages for the customer.

The well-proven Pulverizer ZM 800 has now been renewed: In future the ZM 800 will convince its users with clever optimizations. A new machinery construction has taken place and modifications were realized which offer further operation advantages for the customer.

Visit us at Mumbai

From: 19.01.2017 to 23.01.2017

Visit us in Kielce / poland

Booth:

From: May 22th 2018 to May 25th 2018

Visit us in Lagos!

Booth: T13

From: September, 18th 2018 to September, 20th 2018

Visit us in Moscow

Booth:

From: January 24. 2017 to January 27. 2017

Visit us at Amsterdam!

Booth: B10

From: March 29. 2017 to March 30. 2017

Visit us at Lyon / France

Hall / Booth:

From: November 27th 2018 To: November 30th 2018

Visit us at Wiesbaden – Germany

From: April 26th 2017 to April 28th 2017

Visit us at Guangzhou

Hall: 5.1

Booth: A17

From: May 16. 2017 to May 19. 2017

Visit Us at Targi Kielce

Booth: F-2

From: May 23th 2017 to May 26th 2017

Visit us at Barcelona

From: Okt. 02.2017 To Okt. 06.2017

Hall: P3 Booth: H3

Visit us at Lagos !

Hall / Booth: 1B.1.13

From: March 28. 2017 to March 30. 2017

Visit us at Friedrichshafen Germany !

Hall: A6

Booth: 6201

From 17.10.2017 to 21.10.2017

Visit us at Mexico

From: Oktober 07. 2017 to Oktober 10. 2017

Visit us at Mexico

Booth: 844 & 1043

From: March 08. 2016 to March 11. 2016

Visit us at Brussels

Booth: B20

From: March 22. 2016 to March 23. 2016

Visit Us at Targi Kielce

Booth: F-2

From: May 17th 2015 to May 20th 2015

Visit us in Moscow

Booth: FO C49

From: January 27. 2016 to January 30. 2016

Visit us at Buenos Aires

Booth:

From: June 13. 2016 to June 16. 2016

Visit us at Düsseldorf / Germany

Hall: 9 / Stand: 9D37

From: 19.10.2016 To 26.10.2016

Visit us at Shanghai

Hall: E1

Booth: E09

From: April 25. 2016 to April 28. 2016

Visit us in Moskow

Booth: FO C49

From: 27.01.2015 to 30.01.2015

Visit us at Lima / Peru

Booth: V-338

From: March 03. 2016 to March 06. 2016

Visit us at Gujarat

Hall: 8 Booth: B13

From: 05.02.2015 to 10.02.2015

Visit us at Pazhou, Guangzhou

Booth: 5.1 A07

From: 20.05.2015 to 23.05.2015

Elmia Polymer is Scandinavia’s largest trade fair

focusing exclusively on the plastics and rubber industry.

Visit us at Jönköping / Sweden !

Booth: A04:36

From 21.04.2015 to 24.04.2015

Visit us at Munich Germany !

Booth: C2 / 114

From May 30. 2016 to June 03. 2016

Visit Us at Targi Kielce

Booth: F-2

From: 26.05.2015 to 29.05.2015

Visit us at Friedrichshafen Germany !

Hall: A6

Booth: 6201

From 13.10.2015 to 17.10.2015

To increase the through-put rate of a granulator used for size reduction of loose, unpressed plastics a force feeding technique was developed.

To increase the through-put rate of a granulator used for size reduction of loose, unpressed plastics a force feeding technique was developed.

A screw conveyor is utilized for a technically optimized material feed.

Via conveyor the material is fed in the feed hopper. The transport to the grinding chamber is now no longer only based on the principle of gravitation – in fact the material is now fed to the grinding chamber by one / or more vertically assembled screws. Depending on the required granulator size the number of screws, the rotation speed as well as the drive capacity can vary.

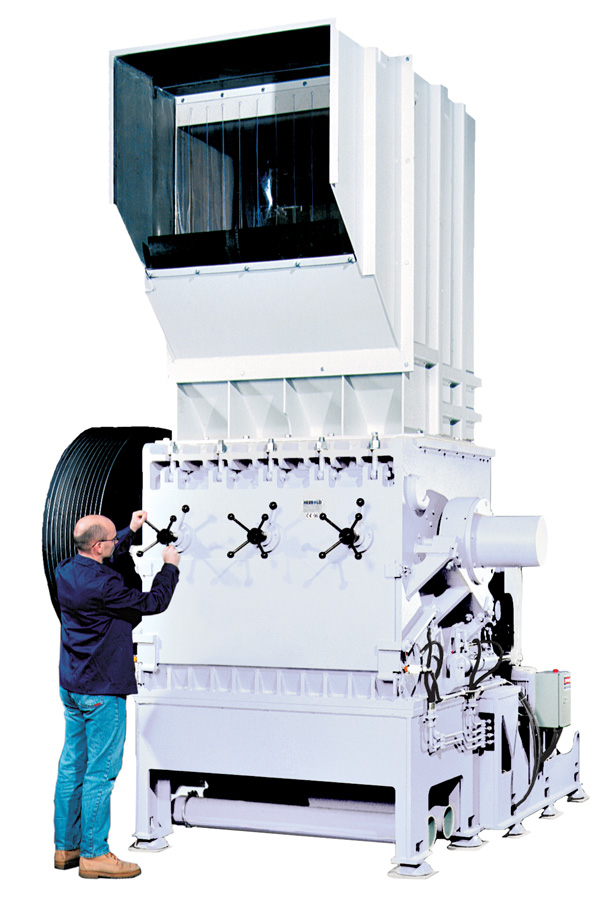

Continue reading… NEUE HERBOLD Maschinen – und Anlagen GmbH located in Sinsheim, Germany have extended their SM granulator range by introducing the new SM1000/… machine.

NEUE HERBOLD Maschinen – und Anlagen GmbH located in Sinsheim, Germany have extended their SM granulator range by introducing the new SM1000/… machine.

The new granulator SM1000/… is completing the upper range of the SM series. This machine has a rotor diameter of 1000mm and will be offered in various widths.

This granulator type is especially designed for applications where a large throughput capacity is required or for the size reduction of large and bulky materials.

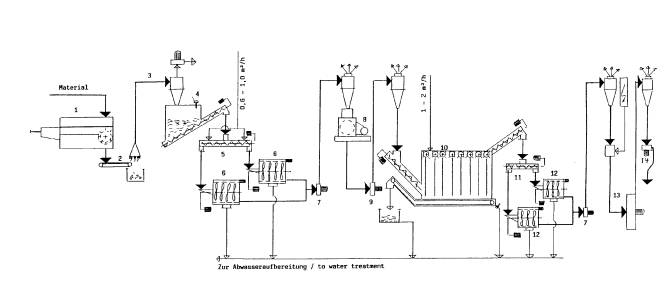

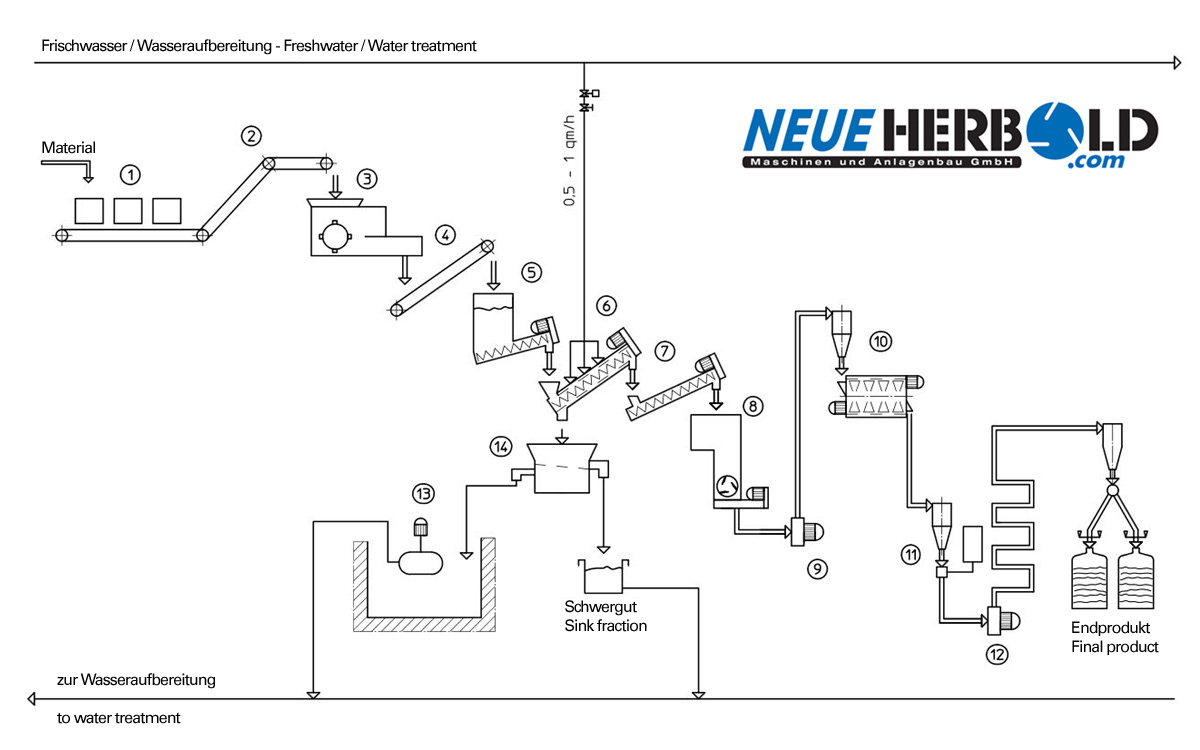

Continue reading… Initial requirements for the installation of a recycling system are the detailed characteristics of the application. Defining the amount of spoilage or contamination in the applicable material and the final usage of the finished product.

Initial requirements for the installation of a recycling system are the detailed characteristics of the application. Defining the amount of spoilage or contamination in the applicable material and the final usage of the finished product.

Initial requirements for the installation of a recycling system are the detailed characteristics of the application: Defining the amount of contamination in the applicable material and the final usage of the finished product. Based on these specifications we would be in a position to engineer and manufacture a complete modular system for the application.

Initial requirements for the installation of a recycling system are the detailed characteristics of the application: Defining the amount of contamination in the applicable material and the final usage of the finished product. Based on these specifications we would be in a position to engineer and manufacture a complete modular system for the application.

Initial requirements for the installation of a recycling system for PET Pressed Bottles are the detailed characteristics of the application: Defining the amount of contamination in the applicable material and the final usage of the finished product. Based on these specifications we would be in a position to engineer and manufacture a complete modular system for the application.

Initial requirements for the installation of a recycling system for PET Pressed Bottles are the detailed characteristics of the application: Defining the amount of contamination in the applicable material and the final usage of the finished product. Based on these specifications we would be in a position to engineer and manufacture a complete modular system for the application.

The NEUE HERBOLD pre-wash screw has been specially designed to discharge forein bodies in the material and

The NEUE HERBOLD pre-wash screw has been specially designed to discharge forein bodies in the material and

for moistening of the material with water.

This is mainly used for the recycling of film for

pre-treatment and for protection of the

intensive washer.

The material which has been washed and size reduced in the wet granulator, falls into a dewatering screw which separates the dissolved contamination.

The material which has been washed and size reduced in the wet granulator, falls into a dewatering screw which separates the dissolved contamination.

NEUE HERBOLD stage dryer Series T are specially designed for gentle drying of PET plastic regrinds.

NEUE HERBOLD stage dryer Series T are specially designed for gentle drying of PET plastic regrinds.

They are suitable for deposition of the surface moisture from the granular plastics. Depending on the temperature, size and structure of the starting product, a surface residual moisture content of about 1 to 2 weight percent is achieved.

Continue reading… NEUE HERBOLD supplies suitable silo systems for all kinds of regrind materials, especially for poor-flowing materials like

NEUE HERBOLD supplies suitable silo systems for all kinds of regrind materials, especially for poor-flowing materials like

film flakes or mono- and multifilaments.

Storage / Ensilage One major component of a recycling plant for plastic scrap is the storage of valuable substances.

Continue reading… Taylor made washing lines for wet recycling of plastics consisting of cutting units / wash units / separation units / drying units)

Taylor made washing lines for wet recycling of plastics consisting of cutting units / wash units / separation units / drying units)

NEUE HERBOLD Maschinen- und Anlagenbau GmbH, located in Sinsheim/Germany manufactures and sells complete washing lines for the recycling of plastics waste. Prior to re-pelletizing the plastic waste must be size reduced, washed and if necessary foreign materials separated.

Continue reading… Pre-Wash drum for Separation of rough contamination

Pre-Wash drum for Separation of rough contaminationTo prevent damages to the downstream grinding and washings systems,

NEUE HERBOLD offers prewash devices like the pre-wash drum type TW.

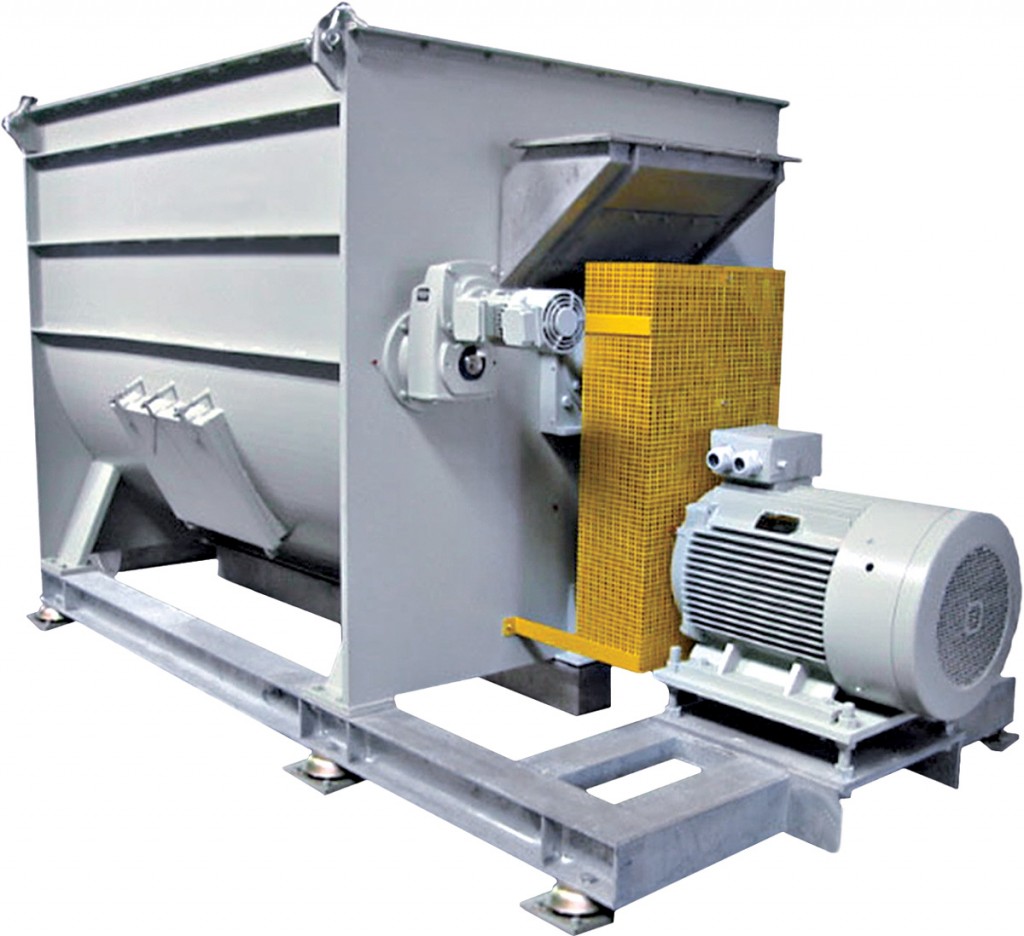

NEUE HERBOLD Holding Silos / Film Silos FS Series are developed for the intermediate storage of material thas does not flow easily. Size reducted film (film flakes), fibres, mono and multifilaments, etc.

NEUE HERBOLD Holding Silos / Film Silos FS Series are developed for the intermediate storage of material thas does not flow easily. Size reducted film (film flakes), fibres, mono and multifilaments, etc.

They differ from conventional round silos mainly because of their horizontal design with single or double discharge screws fitted horizontally to the bottom of the unit.

The NEUE HERBOLD – Separation Tanks Type TB are used for separation of plastics with various densities, primarily for film flakes, granulate from PET bottles and other rigid types of plastics. Depending on the application, floating particles like film falkes or sinking particles like PET bottle flakes are separated from other high density plastics. The standard separation tanks are manufactured from stainless steel 1.4301.

The NEUE HERBOLD – Separation Tanks Type TB are used for separation of plastics with various densities, primarily for film flakes, granulate from PET bottles and other rigid types of plastics. Depending on the application, floating particles like film falkes or sinking particles like PET bottle flakes are separated from other high density plastics. The standard separation tanks are manufactured from stainless steel 1.4301.

NEUE HERBOLD – Thermal Dryer TT Series is a down stream unit after the mechanical dryer. It is designed to achieve a final material moisture of 3% or less.

NEUE HERBOLD – Thermal Dryer TT Series is a down stream unit after the mechanical dryer. It is designed to achieve a final material moisture of 3% or less.

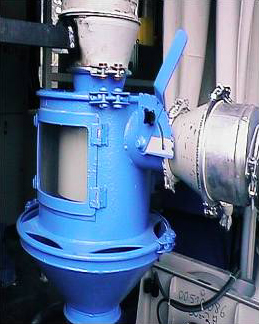

The material is fed through a cyclone. A heater supplies hot air on a continuous basis and is equipped with a temperature control unit. The required temperature is determined by the rest moisture of the various materials as well as the required through put rate. After completion of the drying process the material is blown into film silos (FS Series) or into big-bags for further treatment.

Continue reading… The NEUE HERBOLD series cascade sifter (zig-zag sifter) is utilized for the separation of various types of materials for example; materials that must be separated for environmental reasons, separation for better quality or separation for further processing.

The NEUE HERBOLD series cascade sifter (zig-zag sifter) is utilized for the separation of various types of materials for example; materials that must be separated for environmental reasons, separation for better quality or separation for further processing.

Material separation with the cascade sifter function is as follows:

The input material is “agitated“ through its own weight on the angled walls in a upward direction. At each individual bend on the sifter wall the material must pass through the air current for it to reach the next level. The input material moves in a vertical direction to the air current which created a diagonal air flow.

NEUE HERBOLD fines separator HS Series are capable of removing not only the dust form rigid granulate but also can be applied for removal of dust and fluff (for example in HDPE blow moulding waste or injection moulding waste). The separated fine material is discharged into a container to ensure a dust free environment.

NEUE HERBOLD fines separator HS Series are capable of removing not only the dust form rigid granulate but also can be applied for removal of dust and fluff (for example in HDPE blow moulding waste or injection moulding waste). The separated fine material is discharged into a container to ensure a dust free environment.

NEUE HERBOLD – mechanical Dryer TM Series are used as a downstream component after a washing process. It is used for surface drying of the material fraction primarily for film flakes, granulate from PET bottles and other rigid types of plastics.

NEUE HERBOLD – mechanical Dryer TM Series are used as a downstream component after a washing process. It is used for surface drying of the material fraction primarily for film flakes, granulate from PET bottles and other rigid types of plastics.

The wet material fraction is fed into the upper hopper located on the end of the dryer housing. The rotor of the mechanical dryer transports the material through the dryer from the inlet side to the outlet port. The angular degree of the rotor flights and the rotor speed are detrimental for the material duration time in the dryer.

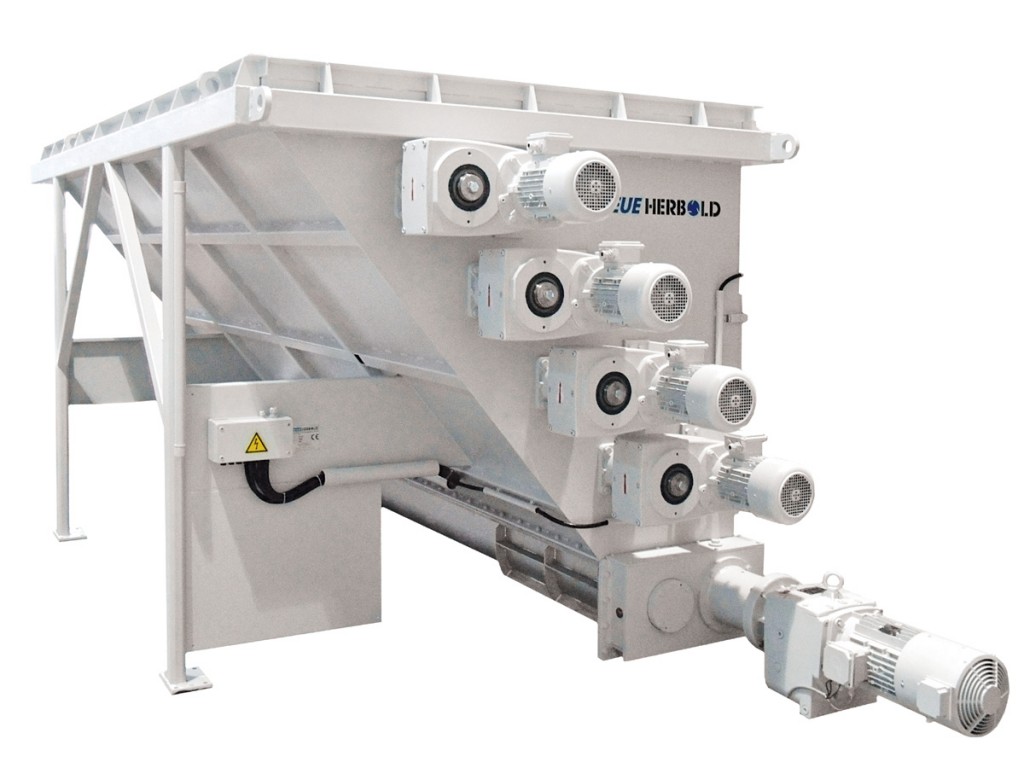

Continue reading… NEUE HERBOLD – Intensive Cleaner IW Series

NEUE HERBOLD – Intensive Cleaner IW Series

The NEUE HERBOLD – Intensive Washer type IW is used for cleaning of material, primarily for film flakes, granulat from PET bottles and other rigid types of plastics.

The material – if cut with a wet granulator – is extremely wet and fed into the upper hopper, which is located on the edge of the dryer housing. An additional nozzle for spraying-in additional water is available as an option.

Continue reading… NEUE HERBOLD – Single Shaft Shredders HZR Series are mainly used for pre-cutting of bales, scrap , tires

NEUE HERBOLD – Single Shaft Shredders HZR Series are mainly used for pre-cutting of bales, scrap , tires

energetic utilization of waste as well as post consumer waste.

The Single Shaft Shredder are equiped with a slow operation rotor. A hydraulically controlled ram feeder transports the feeding material into the cutting area of the rotor.

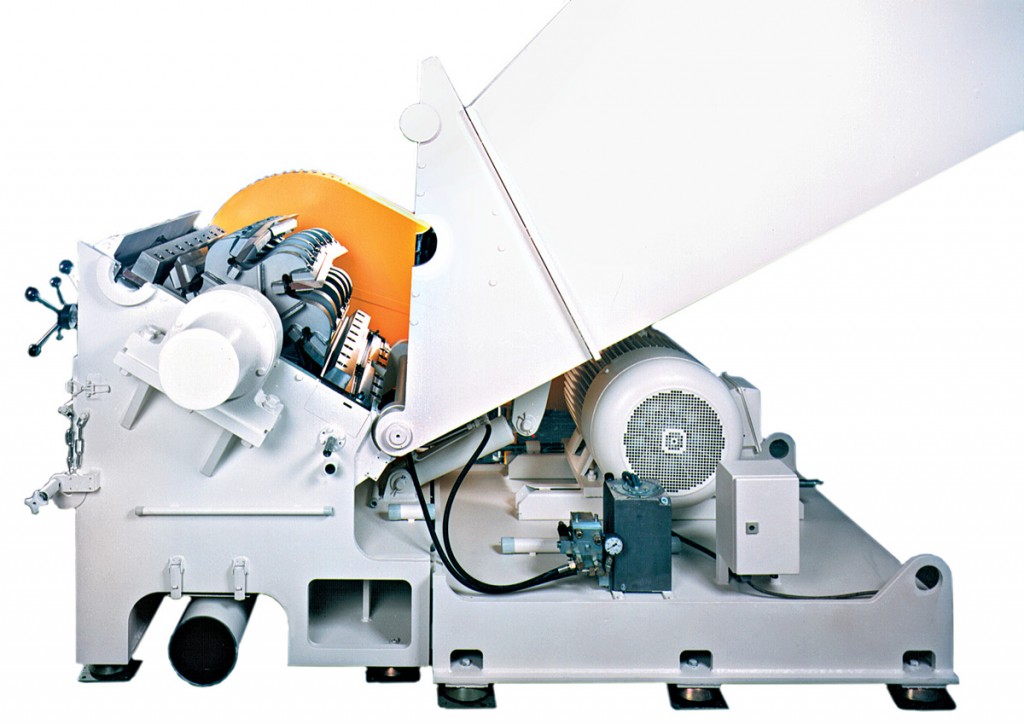

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.

When utilizing a 800 mm (32 in.) rotor diameter in conjunction with a 2000 mm (79 in.) rotor width and 315 kw (425 hp) drive motor depending on the specific screen size through put rates of 15,000 kgs/h (33,000 lbs/h) can be achieved.

SX series granulators are designed with rotor and stator knives that are “V“ or chevron formed counter angled to each other producing a true scissors type cutting action.

NEUE HERBOLD SMV series granulators are specially designed for all universal types of applications. Through simple modification the SMV series granulators can be used for size reduction of forms of hollow bodied parts from various types of plastics, of film of BOPP/BOPET/PP in-line, off-line and sheet applications, PP-big bag and bottle crates

NEUE HERBOLD SMV series granulators are specially designed for all universal types of applications. Through simple modification the SMV series granulators can be used for size reduction of forms of hollow bodied parts from various types of plastics, of film of BOPP/BOPET/PP in-line, off-line and sheet applications, PP-big bag and bottle crates

NEUE HERBOLD – Polystyrene shredders RL Series are used for size reduction of EPS and PUR Foam.

NEUE HERBOLD – Polystyrene shredders RL Series are used for size reduction of EPS and PUR Foam.

Unlike the granulators for size reduction of plastics, the RL shredder operates with a cross beater rotor, without rotor knives, in order to maintain the cell structure of the material.

The granulate size is determined by the distance between the cutting instruments as well as the screen hole size.

Continue reading… NEUE HERBOLD SB screw shredder / bale breaker is engineered and manufactured with a two fold main function. Its heavy duty design makes it ideal for the size reduction of voluminous materials, wooden pallets, cable drums, sheets of insulation, porous building blocks and when used in the PET bottle size reduction can easily and effectively achieve a cluster free break down of PET baled bottles.

NEUE HERBOLD SB screw shredder / bale breaker is engineered and manufactured with a two fold main function. Its heavy duty design makes it ideal for the size reduction of voluminous materials, wooden pallets, cable drums, sheets of insulation, porous building blocks and when used in the PET bottle size reduction can easily and effectively achieve a cluster free break down of PET baled bottles.

The NEUE HERBOLD Shredder Type HZR 1300/4 is especially designed for the effective pre-cutting of thick-walled, high impact pipe up to a maximum of 1200 mm diameter, 6 m in length as well as for start-up lumps.

The NEUE HERBOLD Shredder Type HZR 1300/4 is especially designed for the effective pre-cutting of thick-walled, high impact pipe up to a maximum of 1200 mm diameter, 6 m in length as well as for start-up lumps.

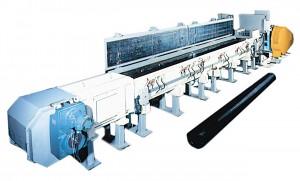

NEUE HERBOLD SR + LP series granulators are designed and manufactured for the size reduction of full length profiles and pipes eliminating the need to pre-cut the material into shorter lengths.

NEUE HERBOLD SR + LP series granulators are designed and manufactured for the size reduction of full length profiles and pipes eliminating the need to pre-cut the material into shorter lengths.

The NEUE HERBOLD ZM series pulverizer (pulveriser) is a extremely high out put unit can be supplied with automatic temperature control. The material to be pulverized is vibro feeder fed into fixed and high speed rotating pulverizer (pulveriser) discs.

The NEUE HERBOLD ZM series pulverizer (pulveriser) is a extremely high out put unit can be supplied with automatic temperature control. The material to be pulverized is vibro feeder fed into fixed and high speed rotating pulverizer (pulveriser) discs.

In conjunction with a integrated inner disc that material is centrifically forced through the pulverizer (pulveriser) discs to the outer chamber for discharge with a down stream material transport system.

The NEUE HERBOLD friction washer FW Series is used to intensively wash plastic materials such as film flakes, granulate to include PET bottle flake and other types of rigid plastics.

The NEUE HERBOLD friction washer FW Series is used to intensively wash plastic materials such as film flakes, granulate to include PET bottle flake and other types of rigid plastics.

The friction washers are mounted on an inclined frame. The material enters at the lower end of the washer with vertical in-feed. The special angular flights in conjunction with the high rpm of the shaft transport the material in an inclined direction toward the top of the unit and simultaneously executes the washing phase.

Applications

Applications

NEUE HERBOLD GS series guillotines are used for the pre-size reduction of monofilament bales such as from fibre, bands or tapes, tacky film packages, extremely large lumps, start-up purgings or rubber bales.

Guillotine Shears series guillotines rigid all welded construction. The guillotine knife is mounted in a double sided channel and operates with two oversized hydraulic cylinders which meet the horizontal stator bar. The stator bar is fully adjustable to insure a precise and exact cut of the baled material.

NEUE HERBOLD HM series hammer mills offer flexibility in their application range.

NEUE HERBOLD HM series hammer mills offer flexibility in their application range.

Through the installation of material oriented rotor milling hammers tools various types of brittle plastics such as electronic scrap, wood scrap, and organic insulation material.

Continue reading…Granulators LM series

size reduction of:

Granulators SM Series

size reduction of:

Granulators SMV series

size reduction of:

Granulators SX series

are specially designed for extremely high output applications.

The application spectrum ranges from the size reduction of:

to the processing of BOPP / BOPET / PP in-line and off-line film extrusion lines.

Granulators SR series

Size reduction of pipes up to 6 meter (20 ft.) length.

Granulators LP/ SP series

Size reduction of profiles up to 6 meter (20 ft.) length.

Mobile size reduction and recycling plants

Because not every rotor is ideally suited for every type of feed material NEUE HERBOLD offers a variety of rotors for different applications. This makes it possible for us to meet the particular requirements of our customers.

The following list shows a summary of the design and main features of the rotors. The complete type number (eg. SM 600/1000-S5-3) of our machines gives information about the rotor design and the number of rows of cutters.