Initial requirements for the installation of a recycling system are the detailed characteristics of the application.

- Defining the amount of contamination in the applicable material

- Defining the final usage of the finished product

Based on these specifications we would be in a position to engineer and manufacture a complete modular system for the application.

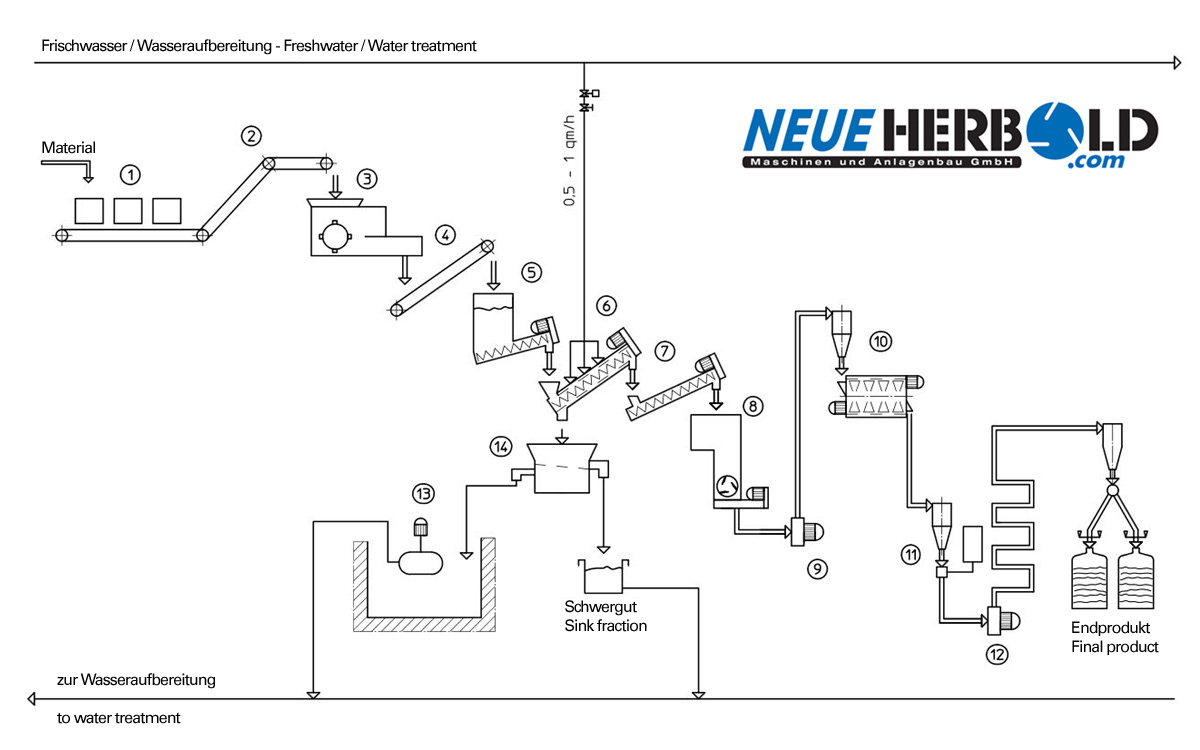

Typical system for recycling of Bottle Crates PE / PP:

1. Holding belt

for loading and continual feeding of material to the inclined conveyor belt

2. Inclined conveyor belt

to transport the material to the down stream granulator

3. Shredder (HZR / ZRM)

for pre-size reducing the crates to a initial size of 30-50 mm

4. Discharge conveyor belt

to transport the pre-size reduced material to the holding silo

5. Holding silo (FS Series)

for storage of the pre-shredded material and to consistently feed the down stream equipment

6. Pre-separating/pre-soaking screw

to separate foreign material such as glass, metal and stones to protect the down stream granulator and mechanical drier and to achieve a higher quality final product

7. Transport screw

for dewatering and further transport of the material to the granulator

8. Granulator

for size reduction of the pre-shredded material to a particle size of approx. 10 mm

9. Material transport system

for discharging the material from the granulator

10. Mechanical dryer (TM series)

for mechanical surface drying of the material

11. Thermal dryer (TT series)

for secondary drying of the material to a residual moisture content of less then 1%

12. Pneumatic transport/Big-Bag discharge station

for further transport the material and discharge into big bags

13. Waste water pump

for transporting the contaminated water to the screening machine

14. Screening machine

for screening of loose and swimming particles from the waste water for final discharge to drainage system