Design of NEUE HERBOLD granulators

Design of NEUE HERBOLD granulators

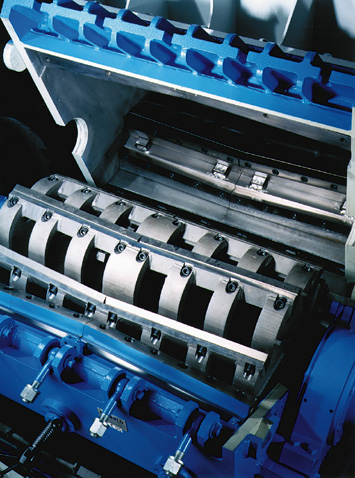

The NEUE HERBOLD Granulators SX series are equipped with the double cross cutting technique. Both the rotating knives, as well as the stator blades in the mill housing are arranged to each other at an angle. This technique ensures a precise cutting gap over the entire working width and for a precise cut. The noise level is thereby significantly reduced.

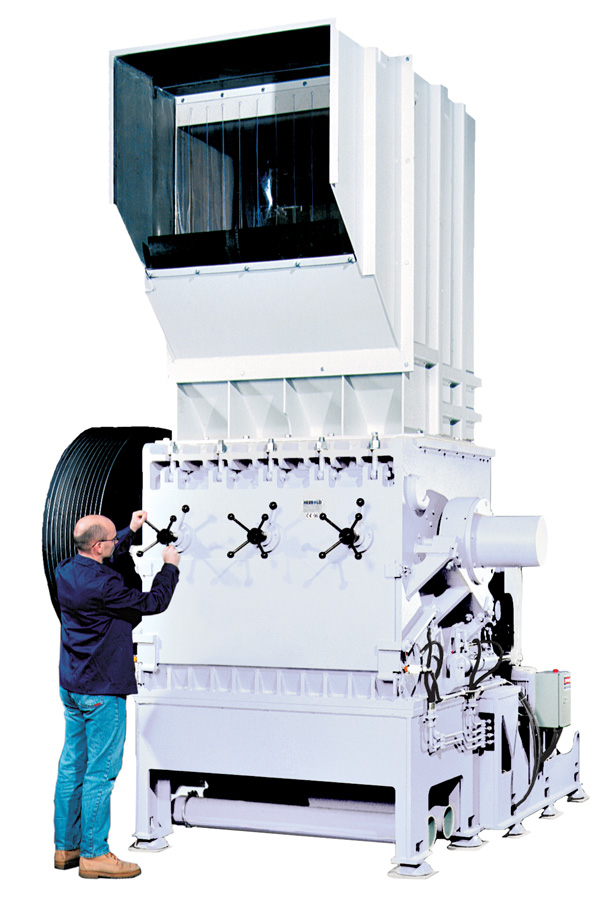

The rotor shaft is housed in stand stock bearings so it is separated from the grinding chamber. This ensures the material to be crushed a safe separation. The granulator SX is different from the other cutting mills by their extremely stable steel construction of the housing design. On request, the mill housing can be equipped with replaceable wear plates.

This series is characterized by its compact design and thereby reduced space requirements. By the arrow-shaped arrangement of cutting tools a lower thermal load on the material is achieved. The material distribution over the working width in the grinding chamber is nearly identical.

Applications of NEUE HERBOLD granulators

The NEUE HERBOLD granulators of the SX series are high performance granulators. The following range of applications covers the SX series:

- film

- tangled or bunched tapes and bands

- PP big bags

- crates

- hollow containers

- to the processing of BOPP / BOPET / PP in-line and off-line film extrusion lines

With a rotor diameter of 600 mm and 800 mm and with working widths of 1000 mm to 2000 mm and depending on the screen holes and type of feed material throughputs from 2 to 15 tons per hour with a driving power of the granulators from 90 kW to 315 kW can be achieved.

Advantages of NEUE HERBOLD granulators

Advantages of NEUE HERBOLD granulators

- extremely high through put rates

- reduced space requirement due to compact design

- energy-saving size reduction

- low noise level due to double-cross cutting knife configuration

- easy cleaning due to “clam shell opening characteristics

- reduced down time for rotor and stator knife replacement due to pre-adjusted knives

Films, hollow bodies and lumps of various plastic materials can be processed by simple modifications. Experiments in our laboratory indicate that up to 20% energy savings for S series was achieved by the optimization of the rotor and housing construction. Likewise, the work safety was increased by improving the handling. The NEUE HERBOLD Granulators SX series are designed for the toughest conditions and suited to the most diverse requirements of modern recycling companies.

The adjustment of the rotor and stator takes place outside the machine in a specially designed setting gauge. The adjusting screws in the rotor and in the mill housing are fixed at delivery that adjustment screws in the cutting blade to be adjusted according to the regrinding state. The adjustments of the cutting blades can be performed during the use of the granulator.

For rotors with adjustable blades a setting gauge is provided for presetting outside the machine. The correct and careful adjustment of the cutting gap is critical to the performance of the granulator.

Technical specifications of NEUE HERBOLD granulators

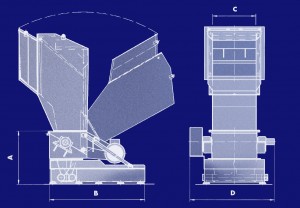

| A (mm) |

B (mm) |

C (mm) |

D (mm) |

E (mm) |

|

| Granulator type SX 800/1200 | 1645 | 2790 | 1304 | 2584 | 940 |

| Granulator type SX 800/1600 | 2063 | 2700 | 1584 | 2819 | 940 |

| Granulator type SX 800/2000 | 2000 | 2730 | 2104 | 3384 | 940 |