Washing / Drying / Separating with Washing Plants by NEUE HERBOLD

NEUE HERBOLD produces and distributes complete recycling systems and washing plants. This also includes washing plants, separation- and drying-systems. The tasks of NEUE HERBOLD systems such as the separating and drying of the conditioned plastics include the washing of used and contaminated plastics wastes.

Washing Plants

The conditioning of contaminated plastics include the removal of packing materials such as foils and pallets / packing straps Adhering residues such as paper labels or contaminations at PET bottles are viewed as impurities that will be removed by the NEUE HERBOLD Washing Plants.

Metal detectors are used for the identification and separation of metal parts. They control the material flow in the metal search bridges on the product conveyor and stop it as soon as magnetic metals are identified. These metal parts can now be removed manually. It is also possible to remove these impurities through permanent magnets / above belt magnets.

Contaminations must be removed and this is, for example, possible through the floating / sinking process. Intensive washers, series IW, or friction separators, series FW, clean the granulates of PET bottles, foil chips and similar grinding stock. Another process is, for example, the mechanical separation of coarse foreign matters through a vibrating sieve or a drum sieve. Depending on the further processing of the produced plastics flakes, they must be brought to a certain residual moisture so that they can, for example, be fed to an extruder. To dry the plastics flakes, they will be pre-dried using mechanical dryers of series TM (using the centrifugal process) and, if required, they will be brought to the required final moisture using the thermal dryers of series TT.

Mechanical dryers

Wet granulates / foil flakes will be centrifuged with high rotational speeds against sieves that are mounted at the outside. The sieves will be cleaned continuously to prevent clogging.

Mechanical stage dryers

Special rotors grab the mixture of water and plastics granulate or plastics flakes. It will be accelerated gently and gradually.

Thermal dryers

For this drying unit, the material flow will be charged with hot air – which is, for example, generated by a damper register – to achieve vaporizing of the water and therefore a drying of the grinding stock. The applied drying processes work with hot ambient air or with pre-dried and heated air.

Pre-Wash Screw

The NEUE HERBOLD pre-wash screw has been specially designed to discharge forein bodies in the material and

The NEUE HERBOLD pre-wash screw has been specially designed to discharge forein bodies in the material and

for moistening of the material with water.

This is mainly used for the recycling of film for

pre-treatment and for protection of the

intensive washer.

Continue reading…

Dewatering Screw

The material which has been washed and size reduced in the wet granulator, falls into a dewatering screw which separates the dissolved contamination.

The material which has been washed and size reduced in the wet granulator, falls into a dewatering screw which separates the dissolved contamination.

Continue reading…

Stage Dryer T

NEUE HERBOLD stage dryer Series T are specially designed for gentle drying of PET plastic regrinds.

NEUE HERBOLD stage dryer Series T are specially designed for gentle drying of PET plastic regrinds.

They are suitable for deposition of the surface moisture from the granular plastics. Depending on the temperature, size and structure of the starting product, a surface residual moisture content of about 1 to 2 weight percent is achieved.

Continue reading…

Round Silos

NEUE HERBOLD supplies suitable silo systems for all kinds of regrind materials, especially for poor-flowing materials like

NEUE HERBOLD supplies suitable silo systems for all kinds of regrind materials, especially for poor-flowing materials like

film flakes or mono- and multifilaments.

Storage / Ensilage One major component of a recycling plant for plastic scrap is the storage of valuable substances.

Continue reading…

Washingplants

Taylor made washing lines for wet recycling of plastics consisting of cutting units / wash units / separation units / drying units)

Taylor made washing lines for wet recycling of plastics consisting of cutting units / wash units / separation units / drying units)

NEUE HERBOLD Maschinen- und Anlagenbau GmbH, located in Sinsheim/Germany manufactures and sells complete washing lines for the recycling of plastics waste. Prior to re-pelletizing the plastic waste must be size reduced, washed and if necessary foreign materials separated.

Continue reading…

Pre-Wash Drum

Pre-Wash drum for Separation of rough contamination

Pre-Wash drum for Separation of rough contamination

To prevent damages to the downstream grinding and washings systems,

NEUE HERBOLD offers prewash devices like the pre-wash drum type TW.

Continue reading…

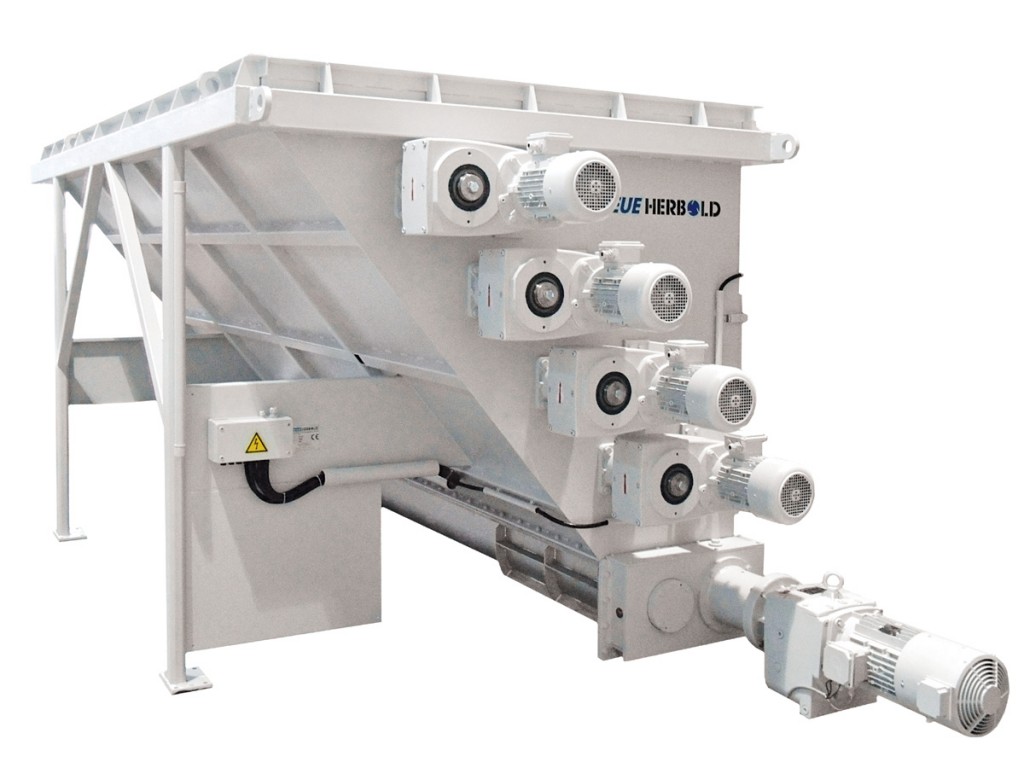

Holding Silos FS

NEUE HERBOLD Holding Silos / Film Silos FS Series are developed for the intermediate storage of material thas does not flow easily. Size reducted film (film flakes), fibres, mono and multifilaments, etc.

NEUE HERBOLD Holding Silos / Film Silos FS Series are developed for the intermediate storage of material thas does not flow easily. Size reducted film (film flakes), fibres, mono and multifilaments, etc.

They differ from conventional round silos mainly because of their horizontal design with single or double discharge screws fitted horizontally to the bottom of the unit.

Continue reading…

Separation Tanks TB

The NEUE HERBOLD – Separation Tanks Type TB are used for separation of plastics with various densities, primarily for film flakes, granulate from PET bottles and other rigid types of plastics. Depending on the application, floating particles like film falkes or sinking particles like PET bottle flakes are separated from other high density plastics. The standard separation tanks are manufactured from stainless steel 1.4301.

The NEUE HERBOLD – Separation Tanks Type TB are used for separation of plastics with various densities, primarily for film flakes, granulate from PET bottles and other rigid types of plastics. Depending on the application, floating particles like film falkes or sinking particles like PET bottle flakes are separated from other high density plastics. The standard separation tanks are manufactured from stainless steel 1.4301.

Continue reading…

Thermal Dryer TT

NEUE HERBOLD – Thermal Dryer TT Series is a down stream unit after the mechanical dryer. It is designed to achieve a final material moisture of 3% or less.

NEUE HERBOLD – Thermal Dryer TT Series is a down stream unit after the mechanical dryer. It is designed to achieve a final material moisture of 3% or less.

The material is fed through a cyclone. A heater supplies hot air on a continuous basis and is equipped with a temperature control unit. The required temperature is determined by the rest moisture of the various materials as well as the required through put rate. After completion of the drying process the material is blown into film silos (FS Series) or into big-bags for further treatment.

Continue reading…

Cascade Sifter ZS

The NEUE HERBOLD series cascade sifter (zig-zag sifter) is utilized for the separation of various types of materials for example; materials that must be separated for environmental reasons, separation for better quality or separation for further processing.

The NEUE HERBOLD series cascade sifter (zig-zag sifter) is utilized for the separation of various types of materials for example; materials that must be separated for environmental reasons, separation for better quality or separation for further processing.

Material separation with the cascade sifter function is as follows:

The input material is “agitated“ through its own weight on the angled walls in a upward direction. At each individual bend on the sifter wall the material must pass through the air current for it to reach the next level. The input material moves in a vertical direction to the air current which created a diagonal air flow.

Continue reading…

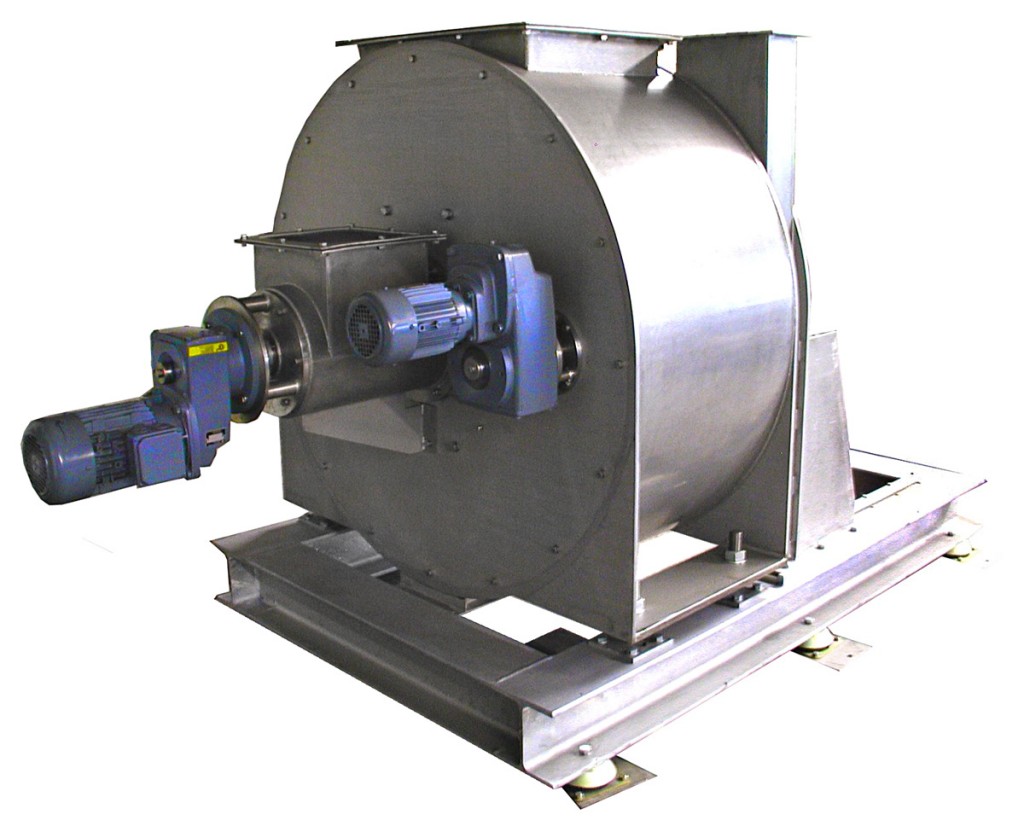

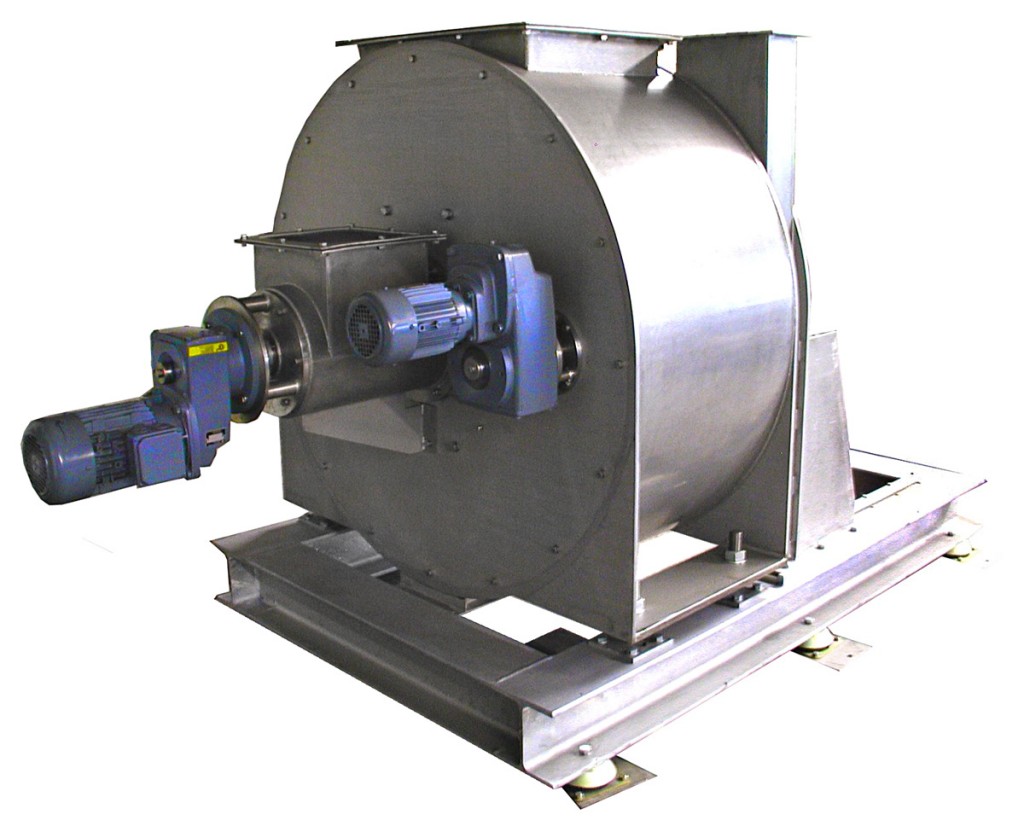

Mechanical Dryer TM

NEUE HERBOLD – mechanical Dryer TM Series are used as a downstream component after a washing process. It is used for surface drying of the material fraction primarily for film flakes, granulate from PET bottles and other rigid types of plastics.

NEUE HERBOLD – mechanical Dryer TM Series are used as a downstream component after a washing process. It is used for surface drying of the material fraction primarily for film flakes, granulate from PET bottles and other rigid types of plastics.

The wet material fraction is fed into the upper hopper located on the end of the dryer housing. The rotor of the mechanical dryer transports the material through the dryer from the inlet side to the outlet port. The angular degree of the rotor flights and the rotor speed are detrimental for the material duration time in the dryer.

Continue reading…

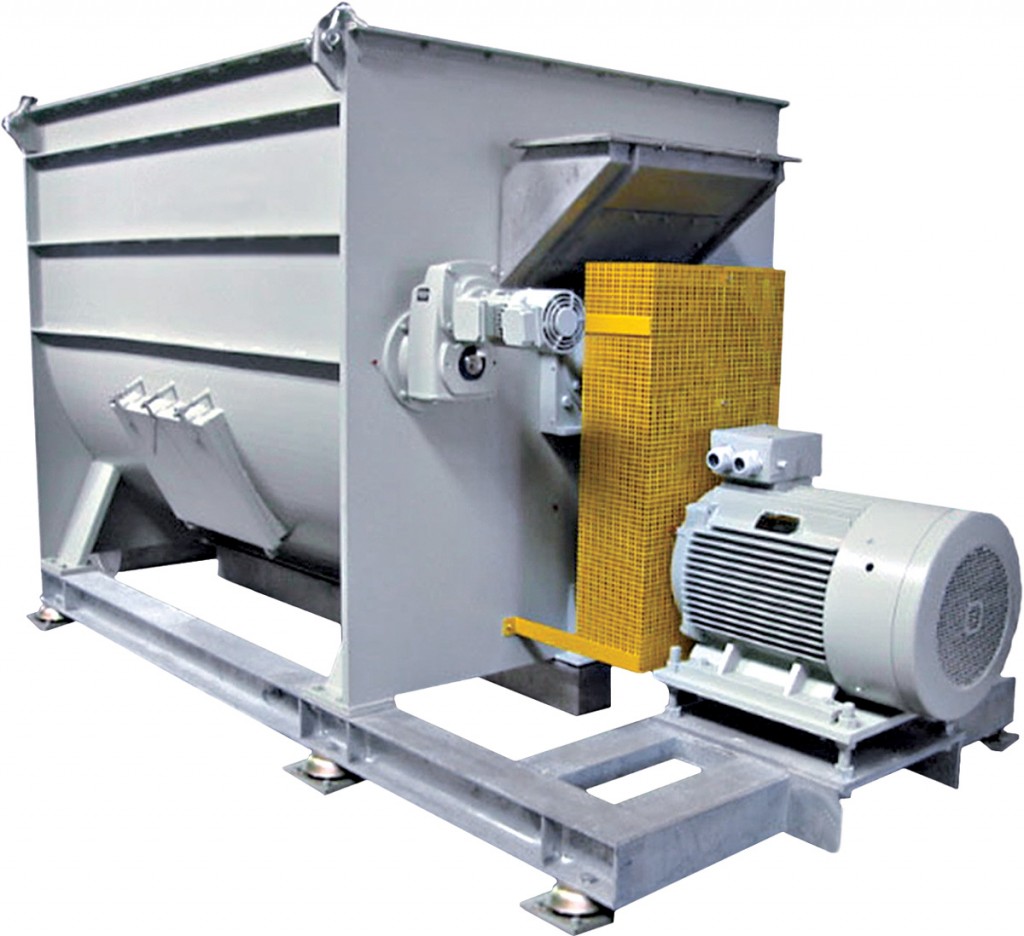

Intensive Cleaner IW

NEUE HERBOLD – Intensive Cleaner IW Series

NEUE HERBOLD – Intensive Cleaner IW Series

The NEUE HERBOLD – Intensive Washer type IW is used for cleaning of material, primarily for film flakes, granulat from PET bottles and other rigid types of plastics.

The material – if cut with a wet granulator – is extremely wet and fed into the upper hopper, which is located on the edge of the dryer housing. An additional nozzle for spraying-in additional water is available as an option.

Continue reading…

Granulator SM

NEUE HERBOLD SM series granulators are specially designed for all universal types of applications.

NEUE HERBOLD SM series granulators are specially designed for all universal types of applications.

The SM series is designed for versatile use and considered a all round granulator for today’s recycler.

SM series granulators are designed with rotor and stator knives that are counter angled to each other producing a true scissors type cutting action. This design results in a cleaner more uniform granulate and reduced heat build up in the granulate. Double angle cut also reduces noise emissions and energy consumption. All knives are straight sharpening and require no special knife sharpening fixture.

Continue reading…

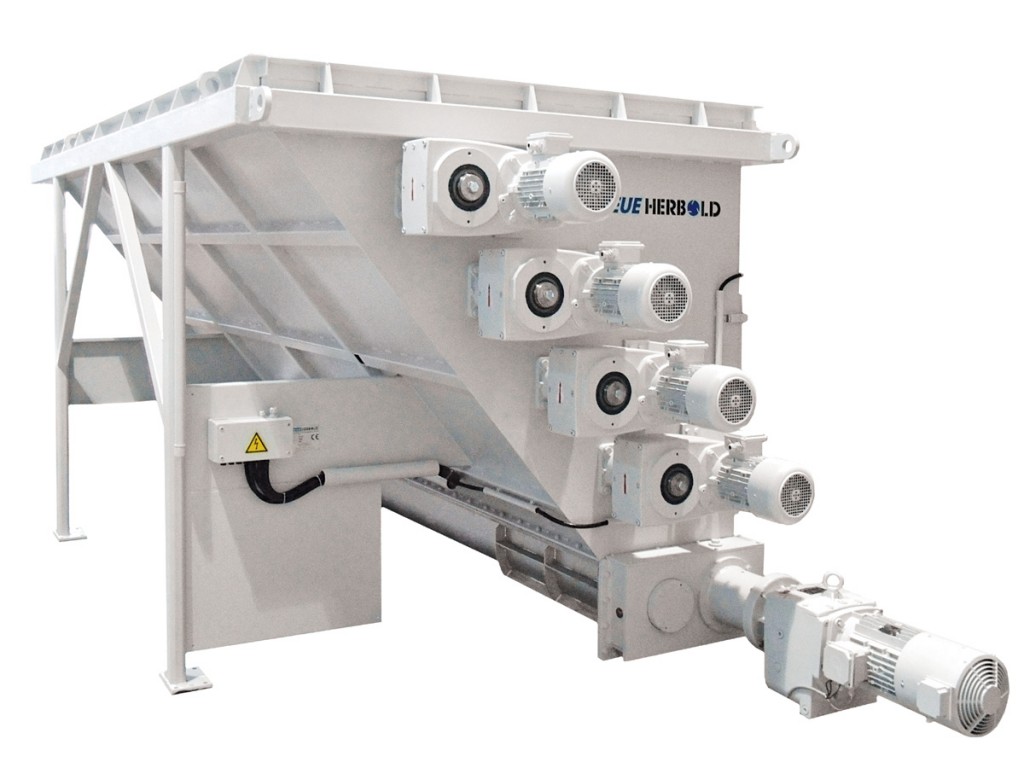

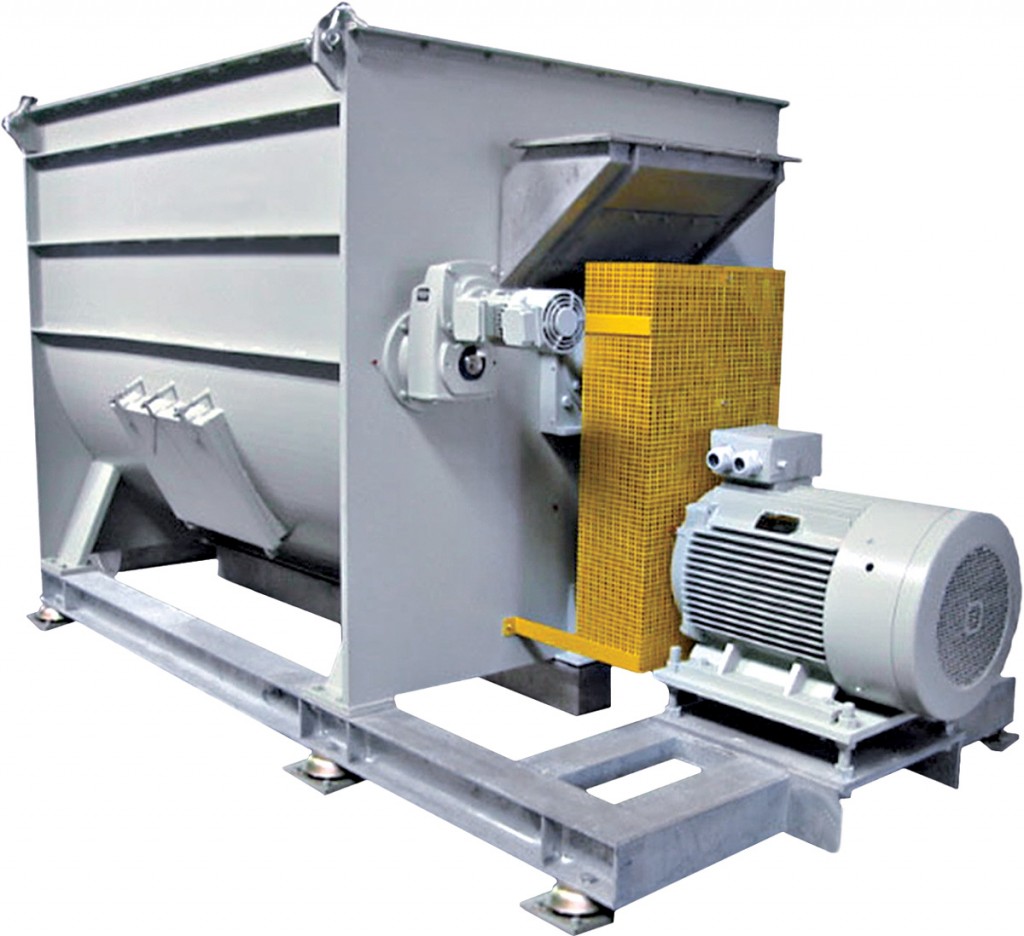

Friction Washer

The NEUE HERBOLD friction washer FW Series is used to intensively wash plastic materials such as film flakes, granulate to include PET bottle flake and other types of rigid plastics.

The NEUE HERBOLD friction washer FW Series is used to intensively wash plastic materials such as film flakes, granulate to include PET bottle flake and other types of rigid plastics.

The friction washers are mounted on an inclined frame. The material enters at the lower end of the washer with vertical in-feed. The special angular flights in conjunction with the high rpm of the shaft transport the material in an inclined direction toward the top of the unit and simultaneously executes the washing phase.

Continue reading…

Mobile size reduction and recycling plant

NEUE HERBOLD offers fully mobile systems designed for specific applications (size-reduction, washing, classification, separation and drying).

NEUE HERBOLD offers fully mobile systems designed for specific applications (size-reduction, washing, classification, separation and drying).

Individual units required for the task are connected with each other; the plant size and the choice of units ensuring unlimited mobility eg. the complete plant can be housed in a container or on a truck.

Continue reading…

The NEUE HERBOLD pre-wash screw has been specially designed to discharge forein bodies in the material and

The NEUE HERBOLD pre-wash screw has been specially designed to discharge forein bodies in the material and