Features and Benefits of NEUE HERBOLD Granulators

Another gain for the massive construction of the granulator is the sturdy steel frame. These are especially the impact zones. No molding parts are used for the prevention of breaking with significant burden.

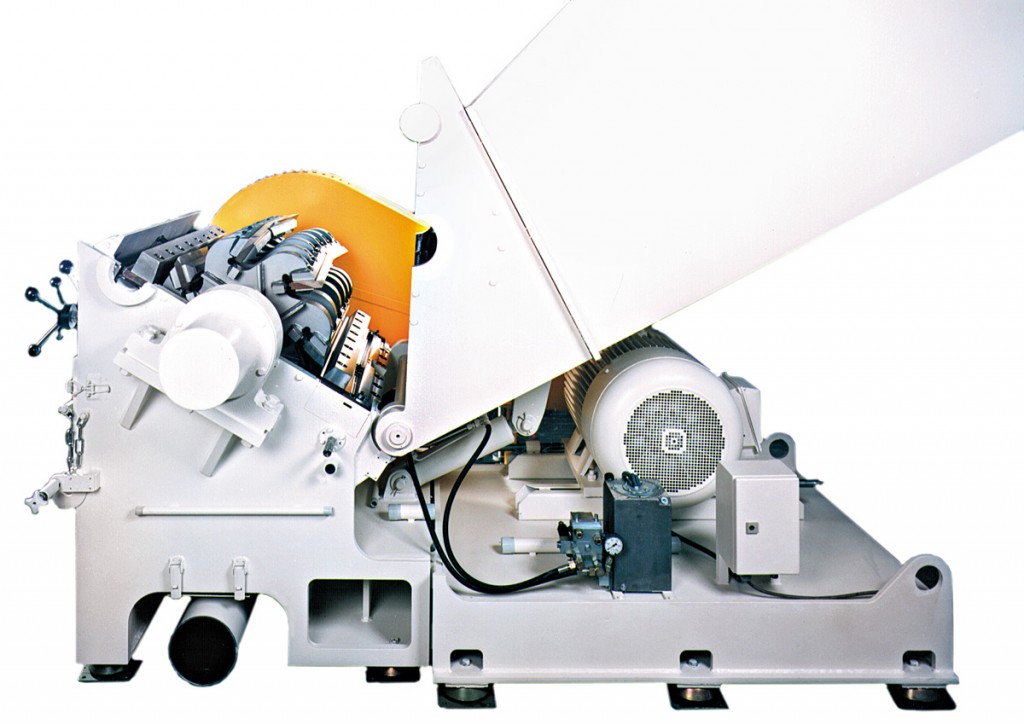

Easy access for cleaning and maintenance

The upper part of the grinding chamber and the inlet funnel are tiltable about an opening device to the rear. This easy access to the lower part of the grinding chamber is provided. There are the rotor, the rotating blades and the front and rear bed knives. The easy accessibility of the wire is ensured.

Granulators LM series

size reduction of:

- loose film ( in-line edge trims)

- hollow containers

- barrels

- crates

- PVC pipes

- thin-walled PE / PP pipes

- profiles (windowprofiles, …)

- automotive bumpers

- web scrap

- injection moulding waste

- hermoforming scrap etc.

Granulators SM Series

size reduction of:

- massive purgings start-up lumps

- rubber bales

- fibre

- massive profiles

- thickwalled pipes

- thickwalled sheet

- thick packages of films etc.

Granulators SMV series

size reduction of:

- thin films (BOPP / BOPET etc.)

- heat sensitive materials

- tapes

- big-bags etc.

Granulators SX series

are specially designed for extremely high output applications.

The application spectrum ranges from the size reduction of:

- film

- tangled or bunched tapes and bands

- PP big bags

- crates or other hollow containers

To the processing of BOPP / BOPET / PP in-line and off-line film extrusion lines.

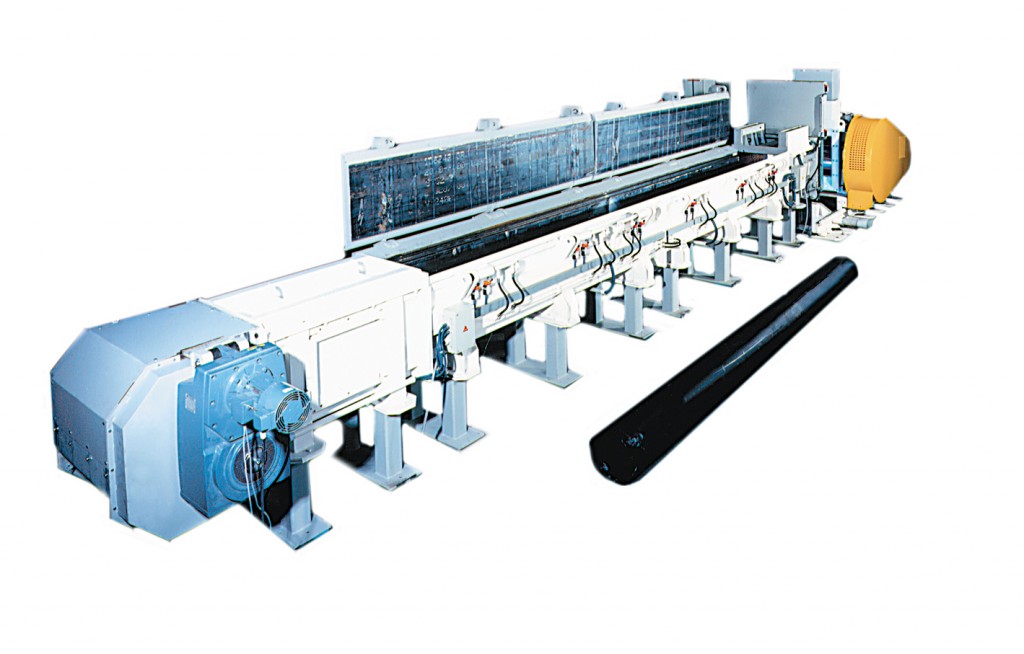

Granulators SR series

Size reduction of pipes up to 6 meter (20 ft.) length.

The material object can be equipped with tilting hopper or material feed chute.

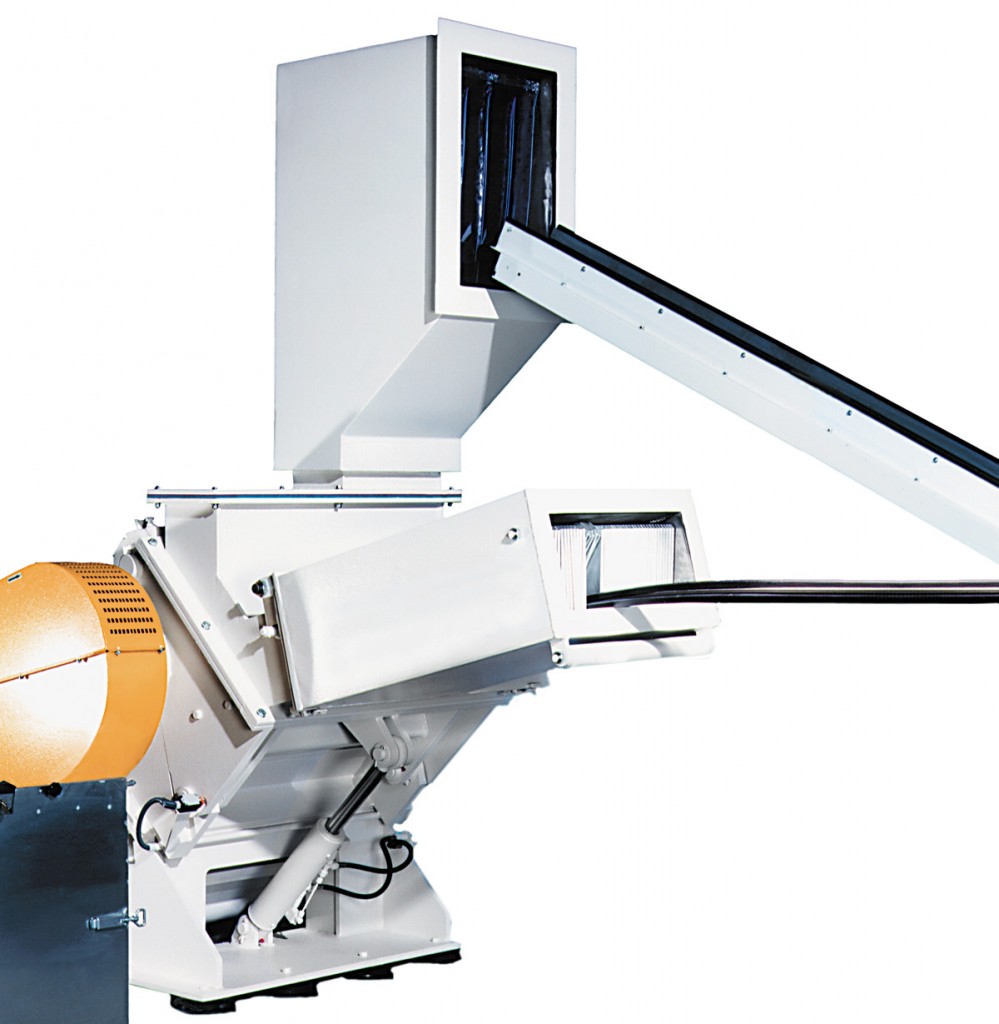

Granulators LP/ SP series

Size reduction of profiles up to 6 meter (20 ft.) length.

The material feed is available with palmrest or forcibly feed via roller pick.

Mobile size reduction and recycling plants

Available rotor designs for our granulators

Improved rotor design

Depending on the task are 4 different types of rotors available. With sophisticated load by raising or an adjustment of the rotor blades is avoided.

In a replaceable blade mounting plate contains the threads of blade bolt. Neither the rotor star nor the blade supports have threaded.