Applications of NEUE HERBOLD pulverizers

Applications of NEUE HERBOLD pulverizers

NEUE HERBOLD ZM series pulverizers are designed for the pulverizing of mid-hard, brittle to high impact plastics that require the final material to be in powder form.

Typical applications are pulverizing of:

- PE granules

- PVC granules

- PC granules and other various types of plastics

The required pulverizer input material must be in a granulate form with a

maximum size of 6-8 mm (1/4-5/16 in.).

Design of NEUE HERBOLD pulverizers

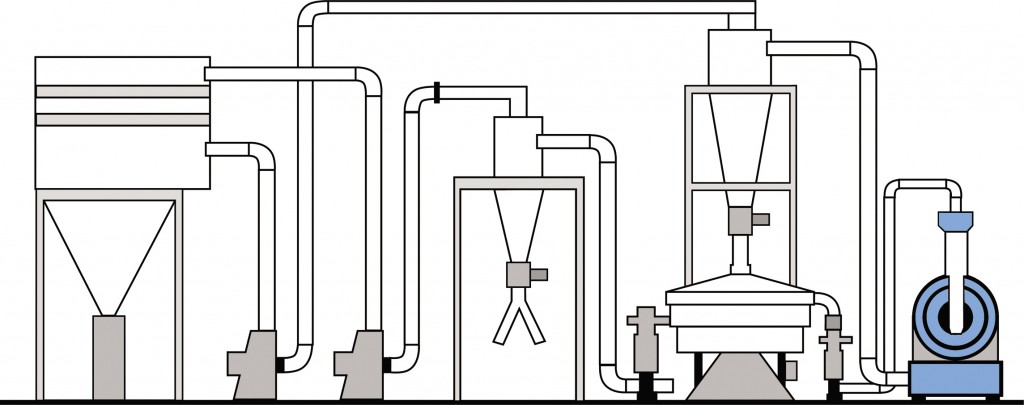

The ZM series pulverizers ares a extremely high out put unit can be supplied with automatic temperature control. The material to be pulverized is vibro feeder fed into fixed and high speed rotating pulverizer (pulveriser) discs.

In conjunction with a integrated inner disc that material is centrifically forced through the pulverizer discs to the outer chamber for discharge with a down stream material transport system.

NEUE HERBOLD ZM series pulverizers (pulverisers) operate without a screening machine. The specific final powder size is dependent on the teeth configuration and the adjustable gap between the pulverizers (pulveriser) discs.

In the event that the application requires a maximum particle size,

a screening machine can be easily integrated into the system.

Advantages of NEUE HERBOLD pulverizers

- extremely high through put rates

- minimal thermal material stress

- longer disc life and reduced re-sharpening costs

- quick and easy disc adjustment and replacement

- cost effective operation

Video – Pulverizer – Type ZM

Technical overview / Performance data

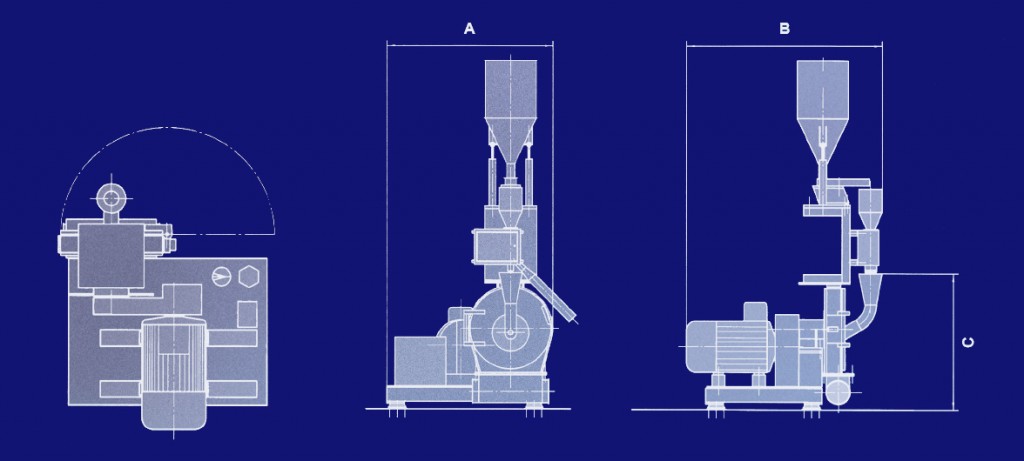

| Type | A (mm) | B (mm) | C (mm) | |

| Pulverizer type ZM 300 | 1350 | 1050 | 1045 | |

| Pulverizer type ZM 500 | 1685 | 1430 | 1180 | |

| Pulverizer type ZM 800 | 2260 | 1140 | 1760 |