Applications of NEUE HERBOLD granulators

Applications of NEUE HERBOLD granulators

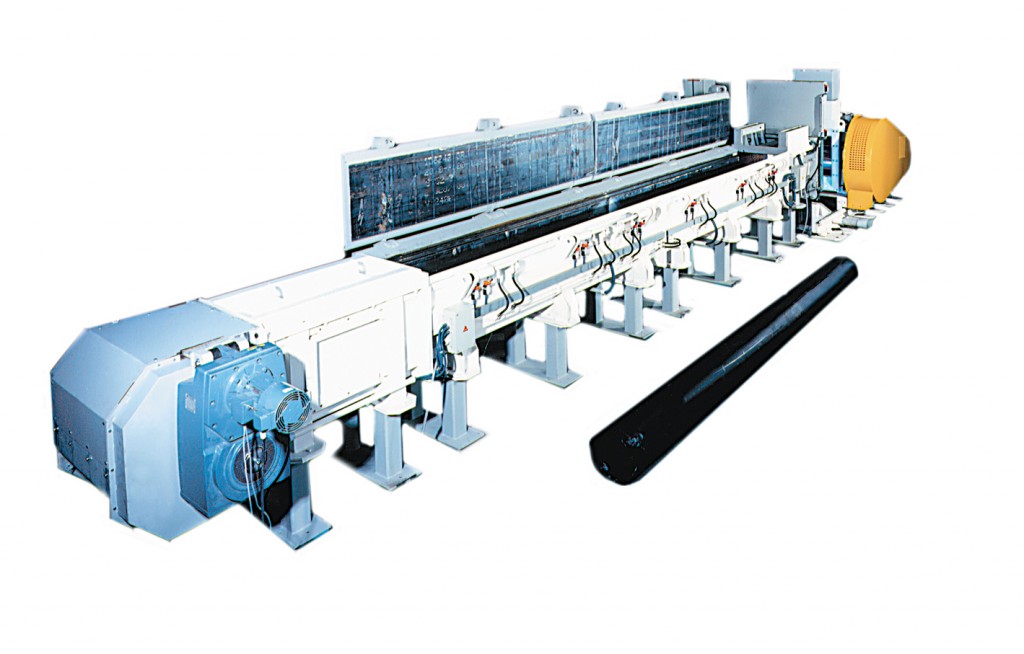

With the NEUE HERBOLD Pipe Granulator SR series, it is possible for size reduction of thick, long pipes and profiles. The horizontal feed allows long profiles or bulky pipes to be processed without deflection and without sawing .

The pipe granulator / profile granulator SR is designed for a quiet protection operation, best throughput performance and maximum safety requirements by an upstream supply tub with a closable lid.

This professional and efficient system is for the size reduction of thick and thin walled pipes and profiles made from most thermoplastics (UPVC, HDPE, PP etc.).

Design of NEUE HERBOLD granulators

NEUE HERBOLD Granulators SR are equipped with a double cross cutting geometry. In the mill housing the rotating and inclined knives work against the tilted stator blade. This cutting technique allows to obtain an accurate average gap over the entire working width and a powerful cut by a low-noise operation.

Alternatively, in sealed form this series is available for the use in washing plants.

By separating the outer rotor shaft from the grinding chamber a foreclosure is ensured to a safely size reduction. The welded and robust housing mill keeps the extreme loads.

SR series

This series is equipped with a horizontally mounted feed trough. A load-dependent controlled feed carriage transports the material to the cutting mill. The escape of material is prevented in each cutting phase through the closed construction. The material is loaded via a feed chute or by a tipping funnel.

The machine of the LP series are used in the crushing of PVC profile waste such as Window profile rods.

Advantages of NEUE HERBOLD granulators

- heavy duty design

- energy-saving size reduction

- low noise level due to double-cross

- cutting knife configuration

- extremely high through put rates

- easy cleaning due to clam shell

- opening characteristics

- reduced down time for rotor and stator knife replacement due to pre-adjusted knives

The adjustment of the rotor and stator takes place outside the machine in a specially designed setting jig.

The adjusting screws in the rotor and in the mill housing are fixed at delivery. The adjustment screws in the cutting blade are to be adjusted according to the regrinding state.

The adjustments to the cutting blade can be performed during the operation of the granulator.

To preset outside the machine (with rotors with adjustable blades) an adjustment tool is provided, which leads to simplification of the knife adjustment and shorten machine downtime when changing knives. The correct and careful adjustment of the cutting gap is essential to the performance of the granulator.

A – Granulator

B – Material gate

C – Rope station

D/E – Material trough

F – Garage

H – Rope drive Station

Video – Size reduction of PVC Pipe production waste

Technical overview / Performance data