Application

Application

The NEUE HERBOLD series cascade sifter ((zig-zag sifter) is utilized for the separation of various types of materials for example; materials that must be separated for environmental reasons, separation for better quality or separation for further processing.

Necessary requirements for effective separation are:

- Specific density

- Material form

- Material surface characteristics

- Material size

Function

Material separation with the cascade sifter function is as follows:

The input material is “agitated“ through its own weight on the angled walls in a upward direction. At each individual bend on the sifter wall the material must pass through the air current for it to reach the next level. The input material moves in a vertical direction to the air current which created a diagonal air flow. This causes the heavy material which has a lower air floatation factor, to separate itself form the lighter fraction and flow with the air current in a upward direction. The degree of separation is dependent upon the amount the stages that are utilized in the complete unit. This is relevant of the type of material to be separated.

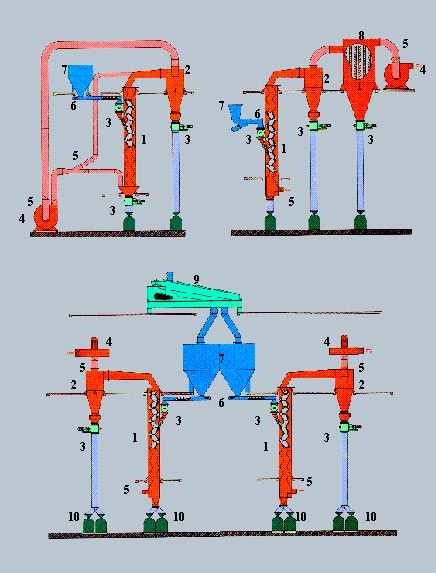

Example of a typical sifter system