Initial requirements for the installation of a system for Recycling of Film Waste are the detailed characteristics of the application:

- Defining the amount of spoilage or contamination in the applicable material

- Defining the final usage of the finished product

Based on these specifications we would be in a position to engineer and manufacture a complete modular system for the application.

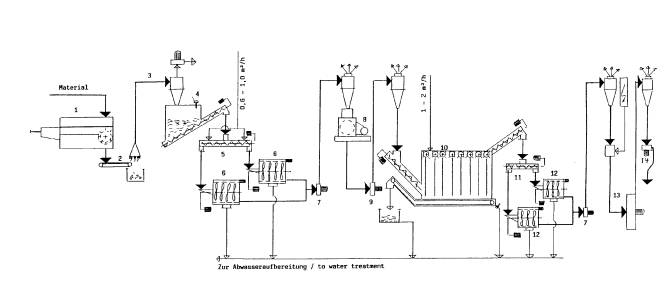

Typical system for processing baled material:

1. Pre-size reduction ( Single-Shaft-Shredder / Two-Shaft-Shredder / Bale Breaker )

for breakdown and/or size reducing

the baled film waste.

The slow rotating pre-size reducer

is equipped with a large capacity

in-feed hopper which will accept

numerous bales for the

pre-size reduction process

2. Discharge conveyor belt

for removal of the size-reduced material from the pre-size reducer

3. High efficient air aspirator (HS series)

is positioned above the discharge

belt for separation of coarse

foreign material from the

material flow and to protect

the down stream components

4. Flake silo (FS series)

for pre-storage and consistent

feeding of the down stream

components

5. Pre-soaking screw

for preparation of the

material to the next

stage intensive cleaner

6. Intensive cleaner (IW series)

for intensive surface

removal of the water

solfable foreign

contamination

from the material

7. Suction Unit

for removal of the material from the intensive cleaner and transport to the down stream granulator

8. Granulator

for size-reduction

of the material to

the final product size

9. Suction Unit

for removal of the material from the granulator

10. Separation tank (TB series)

11. Diverter screw

for transport and diversion of the material to the down stream dryer

12. Mechanical dryer (TM series)

for mechanical

surface drying

of the product

13. Thermal dryer (TT series)

for final drying of the

film flakes to a residual

moisture content of

less then 1% in weight

Recycling of Film Waste

Flow chart DSD film waste