Applications

Applications

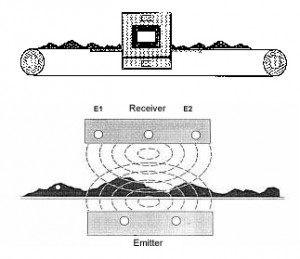

A metal detector bridge is used to detect and protect the size reduction and production systems from damage and destruction. This can be caused by metal contamination that could be found in the feed material. Electronic metal bridges are normally situated on the conveyor feed belt in the size reduction system. ( i.e. granulator in-feed ).

All various types of metals such as stainless steel, or copper are detectable. These types of metal cannot be identified through magnet detection but only through inductive detection. The electronic detector can be used for all metals that are electrically inductive.

Design

The inner ( sender ) detection coil produces a high frequency electro-magnetic field which penetrates the feeding material. This sender coil emits 2 identical current fields which are transmitted to the receiver coil ( E1 and E2 ).

Any metallic contamination passing through this field alters the energy field. The detected unbalance in the field is analysed and converted into a switching impulse.

The main characteristics of double layered detection coils

- detects all types of metals, i.e. aluminium, copper, brass, lead, stainless steel, etc.

- utmost sensitivity

- self monitor system: all necessary functions are constantly monitored. The system is activate through a blinking light and relay switch in the event of a systems fault

- quick and easy sensitivity adjustment of metal detection with dial to include vibration and fault sensor