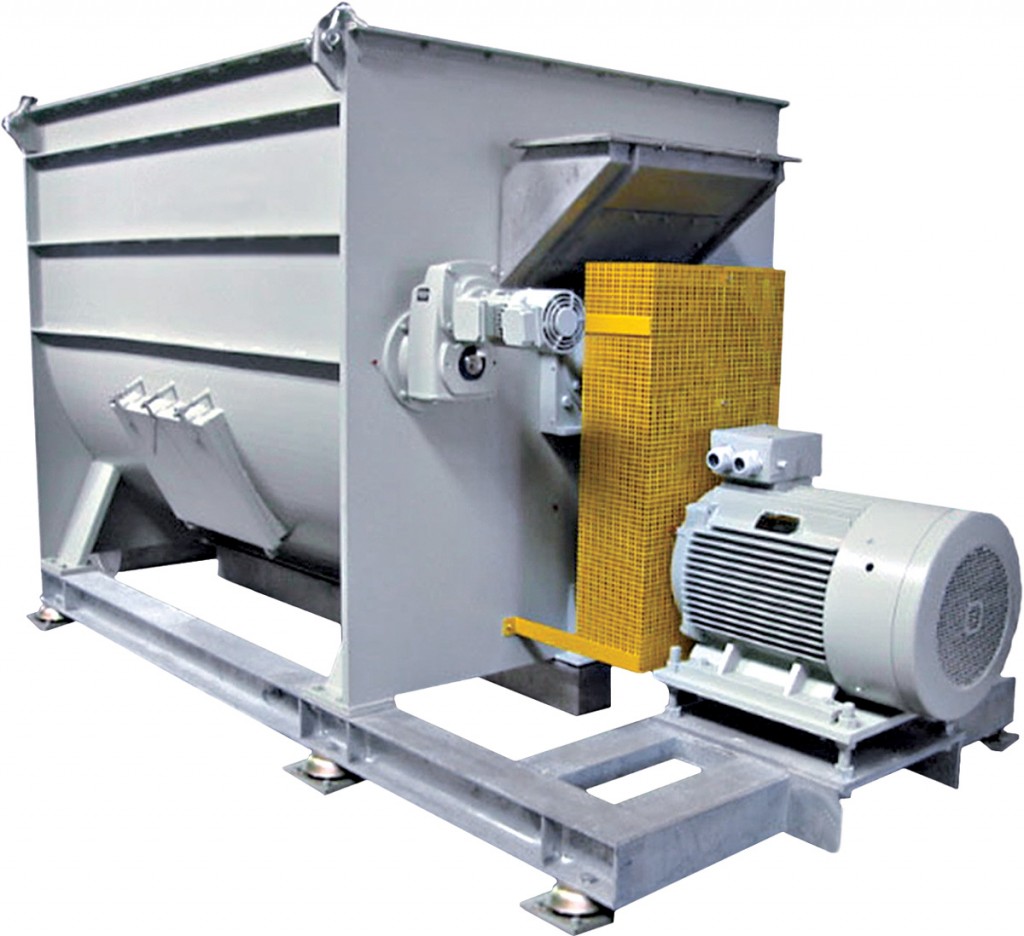

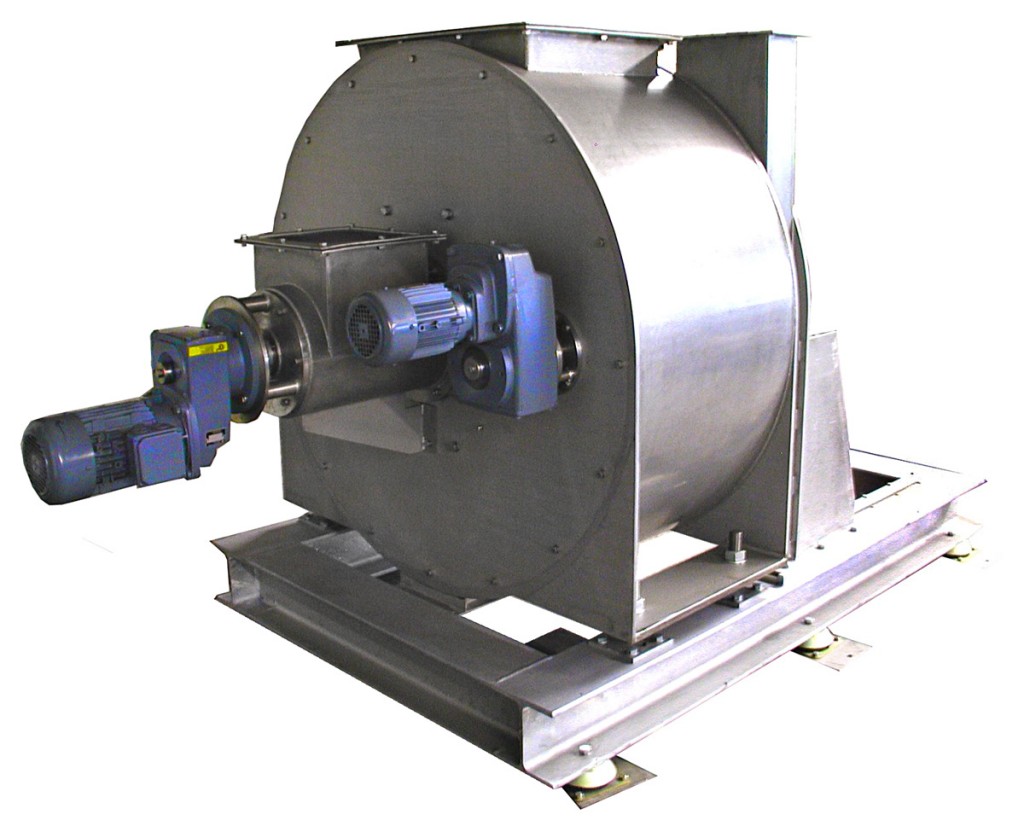

NEUE HERBOLD stage dryer Series T are specially designed for gentle drying of PET plastic regrinds.

NEUE HERBOLD stage dryer Series T are specially designed for gentle drying of PET plastic regrinds.

They are suitable for deposition of the surface moisture from the granular plastics. Depending on the temperature, size and structure of the starting product, a surface residual moisture content of about 1 to 2 weight percent is achieved.

Continue reading…