NEUE HERBOLD stage dryer Series T are specially designed for gentle drying of PET plastic regrinds.

They are suitable for deposition of the surface moisture from the granular plastics. Depending on the temperature, size and structure of the starting product, a surface residual moisture content of about

1 to 2 weight percent is achieved.

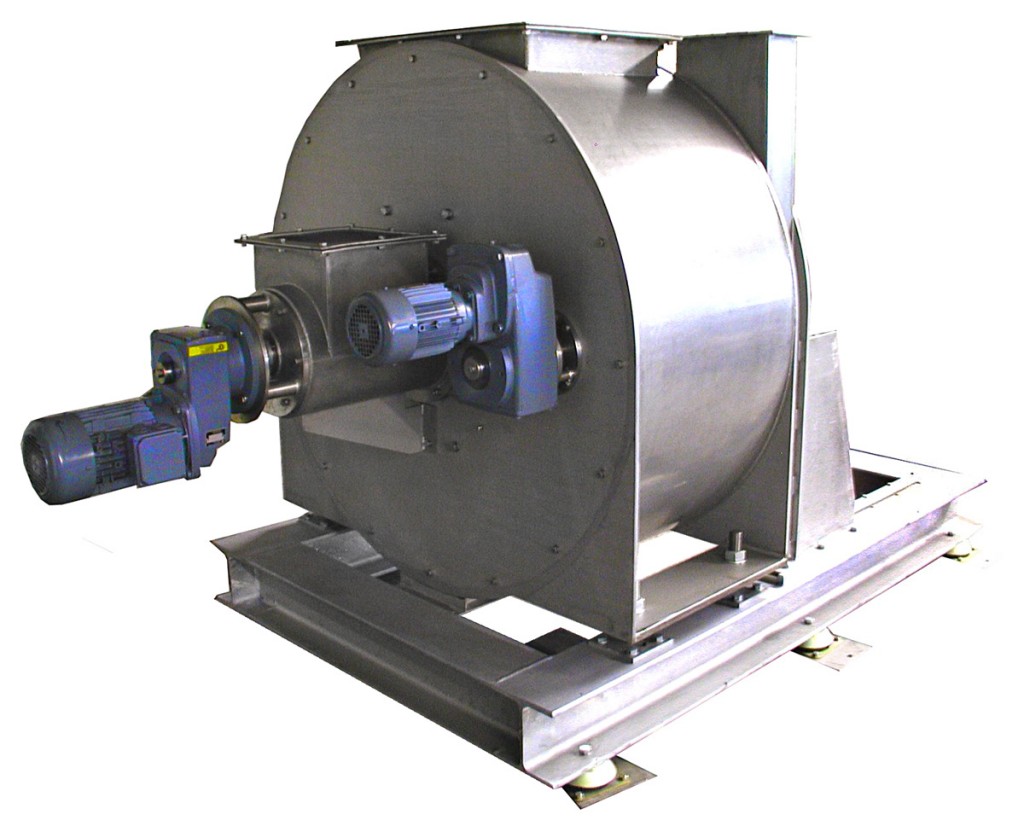

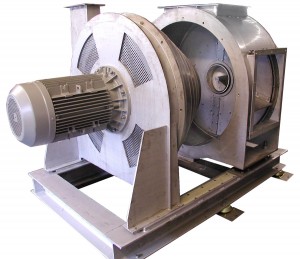

The Grist water mixture is fed to the drying chamber via the feed screw. In the dryer, the material to be ground is detected by a special rotor equipped with blades and transported by the step-shaped screen basket. By this diameter magnifying the ground material in the input is only slightly accelerated to then be accelerated from stage to stage more and thus throw off the adhering water particles. Due to the rotor and screen cradle design the particles are handled carefully and reduces the fines to a minimum.

Via the tangentially arranged outlet channel, the dried product exits the dryer in the air stream. The separated water particles are excreted along with the fines at the bottom case. A continuous cleaning device encircles the outside of the screen basket and the housing inner wall.

Design Features

- Housing, rotor and strainer made of stainless steel

- permanent cleaning device

- low mechanical stress and therefore reduced fines

- low maintenance

- Strainer optionally round

(gentle product load) or polygonal (high detergency)

Mechanical cleaning

The mechanical clearing is done by rubber strips which are mounted to two cleaning brackets which circuit around the screen cage. The outside of the screen cage and the inner wall of the housing are continuously cleaned. The cleaning brackets are driven by a gear motor.

Sizes

|

Type |

T 9/5: |

T 15/5: |

T 12/5: |

|

| Main drive | 18,5 kW | 37 kW | 30 kW | |

| Cleaning | 0,55 kW | 0,75 kW | 0,75 kW | |

| Feed screw | 2,2 kW | 2,2 kW | ||

| Throughput | up to 0,5 to/h | up to 2,2 to/h | up to 1,2 to/h |