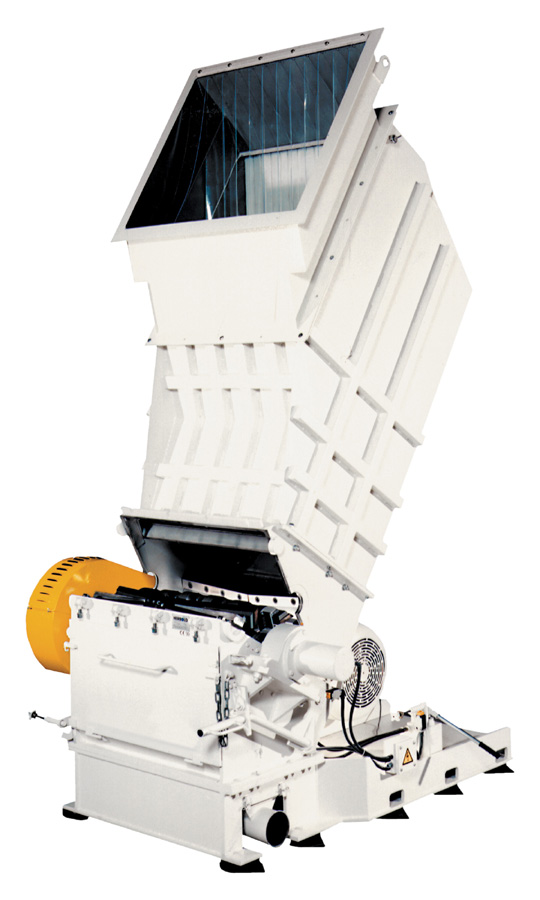

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.

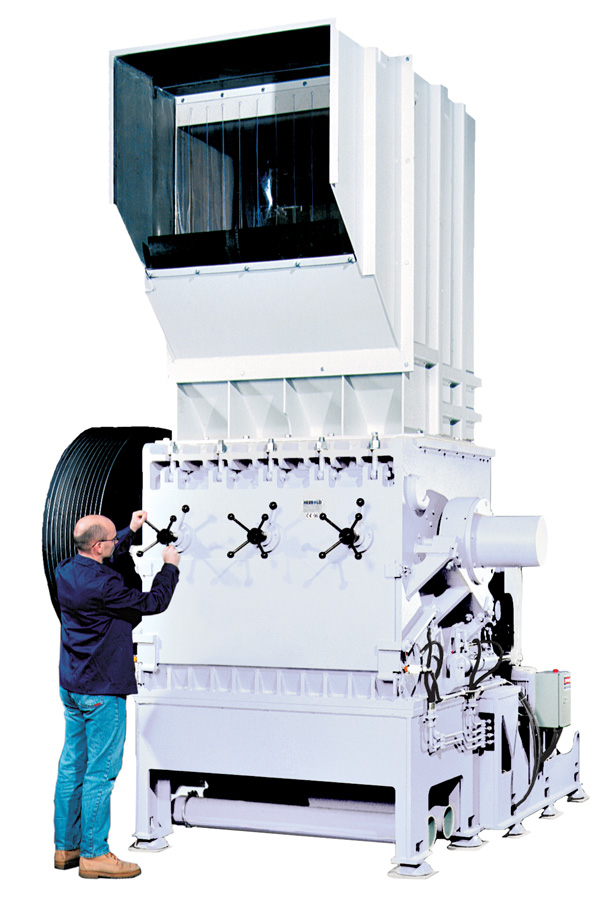

When utilizing a 800 mm (32 in.) rotor diameter in conjunction with a 2000 mm (79 in.) rotor width and 315 kw (425 hp) drive motor depending on the specific screen size through put rates of 15,000 kgs/h (33,000 lbs/h) can be achieved.

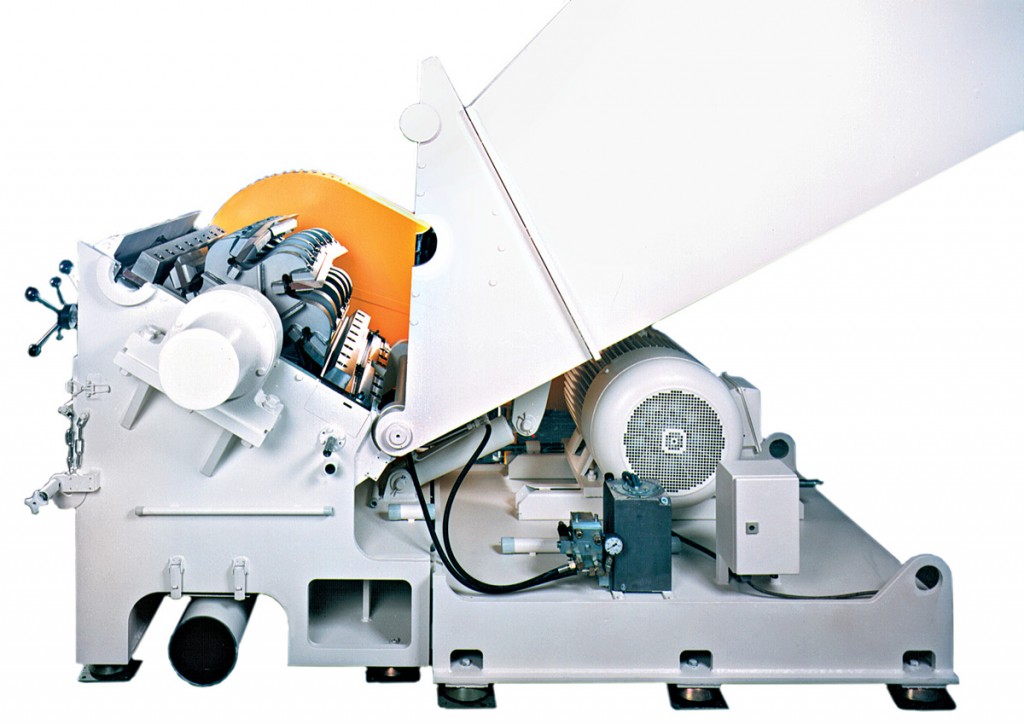

SX series granulators are designed with rotor and stator knives that are “V“ or chevron formed counter angled to each other producing a true scissors type cutting action.