Blog Archives

Phase two of the conditioning is – after the pre-Size-Reduction – the Size-Reduction using Granulators and hammer mills. These machine types are used to crush already pre-crushed particulate materials to the required final size.

Granulators

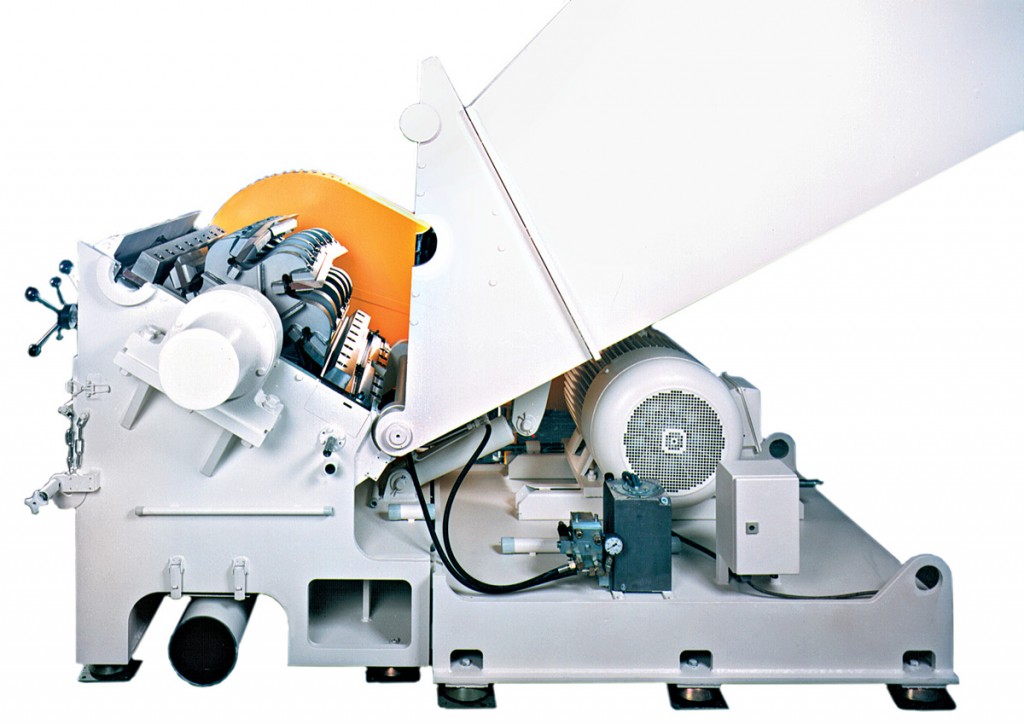

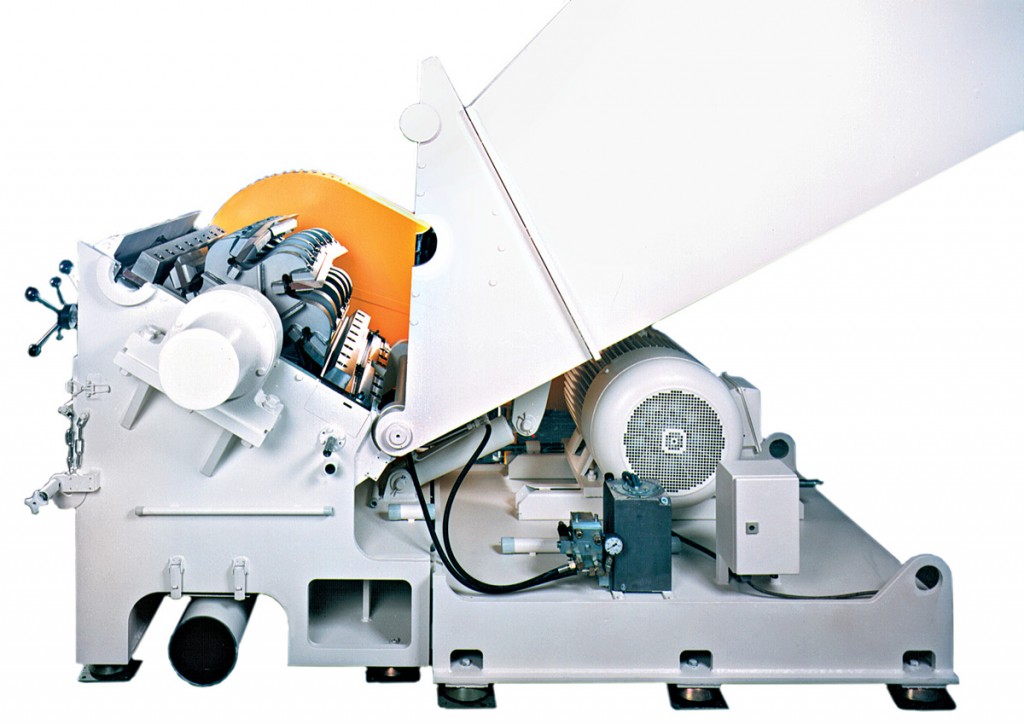

Among others, the different cutting mills process foils, long profiles up to massive chunks. The material is transported through funnels, rotating rotor knifes and stator knifes to the grinding room.

A large benefit for NEUE HERBOLD granulators is the easy access to the grinding space for cleaning purposes, for material change or for required tool changes. This is important for the reduction of standstill times.

We produce all machines exclusively based on a heavy-duty massive steel construction.

Double diagonal cut – economical and precise

The double diagonal cut guarantees a constant cutting gap for the full work width. Therefore, the cutting mills achieve a high throughput with a low noise development while simultaneously saving energy. In addition, the thermal stress of the material is reduced.

Accessory – Blade adjustment jig

The provided blade adjustment jig permits the precise pre-adjustment of the knifes outside the granulators. Since your employees do no adjust the knifes laboriously in the machine, but under good working conditions by using the adjustment jig outside, this results of course also in an improved work protection action as part of the maintenance of our granulators. The exact fine adjustment of the cutting gap guarantees the efficiency and the throughput performance of the granulators.

Rotor types

Different rotor designs are used to satisfy the diverse scopes of work of the material requirements during the size reduction. The different designs permit the processing of soft, hard and impact resistant plastics.

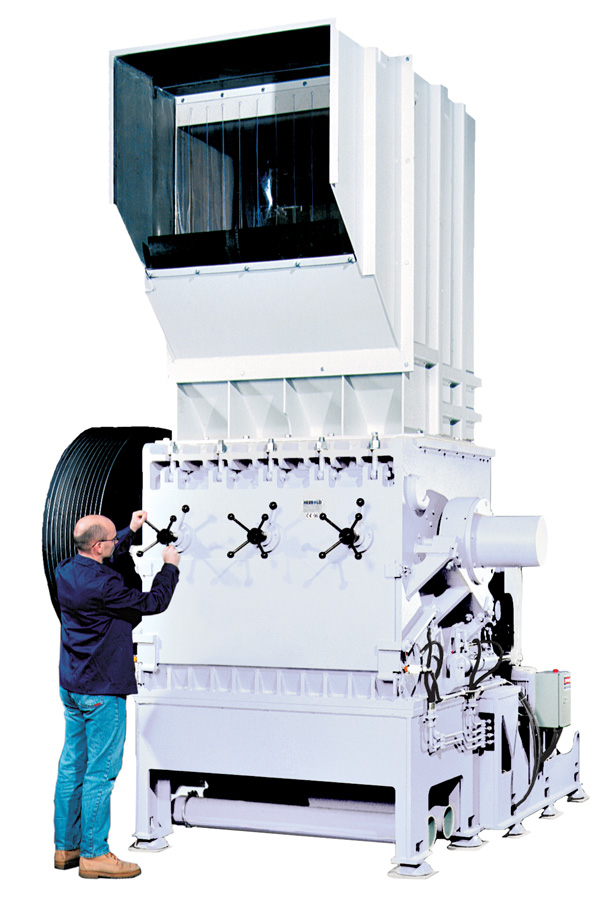

Pipe shredders

The mostly thick-walled pipes in the pipe shredders are fed to the shredder shafts by a ram. Long and heavy pipes will be transported horizontally into the feed trough using load cranes. Short pipe pieces and pipe wastes from a plastics production can be fed manually by the workers. In addition to our described “traditional” pipe shredders, we also offer for shredding tilting feed hoppers for our granulators, series LM and SM, which are used to release the pipes and to feed them to the shredder unit utilizing the gravity principle.

Granulator SX

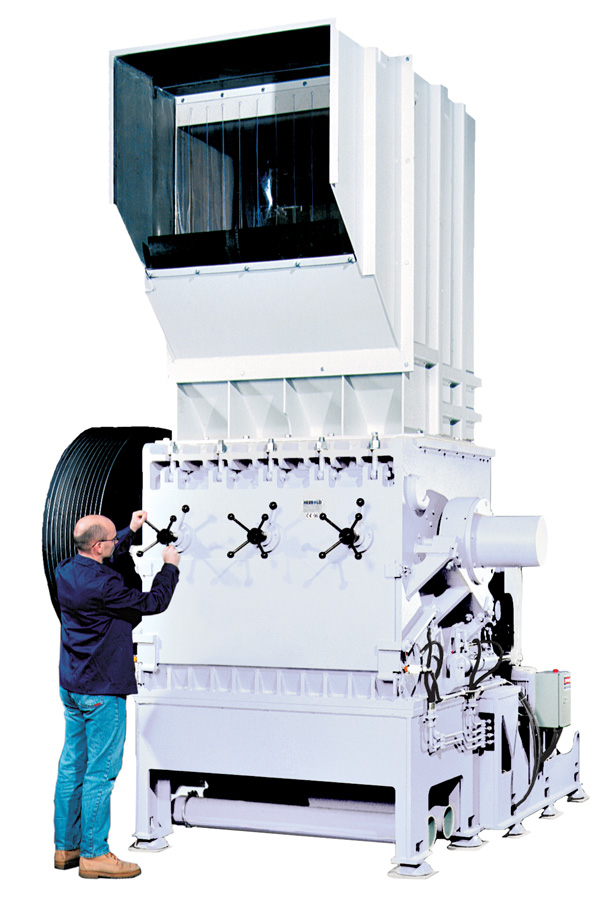

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.

When utilizing a 800 mm (32 in.) rotor diameter in conjunction with a 2000 mm (79 in.) rotor width and 315 kw (425 hp) drive motor depending on the specific screen size through put rates of 15,000 kgs/h (33,000 lbs/h) can be achieved.

SX series granulators are designed with rotor and stator knives that are “V“ or chevron formed counter angled to each other producing a true scissors type cutting action.

Continue reading…

Granulator SMV

NEUE HERBOLD SMV series granulators are specially designed for all universal types of applications. Through simple modification the SMV series granulators can be used for size reduction of forms of hollow bodied parts from various types of plastics, of film of BOPP/BOPET/PP in-line, off-line and sheet applications, PP-big bag and bottle crates

NEUE HERBOLD SMV series granulators are specially designed for all universal types of applications. Through simple modification the SMV series granulators can be used for size reduction of forms of hollow bodied parts from various types of plastics, of film of BOPP/BOPET/PP in-line, off-line and sheet applications, PP-big bag and bottle crates

Continue reading…

Granulator SM

NEUE HERBOLD SM series granulators are specially designed for all universal types of applications.

NEUE HERBOLD SM series granulators are specially designed for all universal types of applications.

The SM series is designed for versatile use and considered a all round granulator for today’s recycler.

SM series granulators are designed with rotor and stator knives that are counter angled to each other producing a true scissors type cutting action. This design results in a cleaner more uniform granulate and reduced heat build up in the granulate. Double angle cut also reduces noise emissions and energy consumption. All knives are straight sharpening and require no special knife sharpening fixture.

Continue reading…

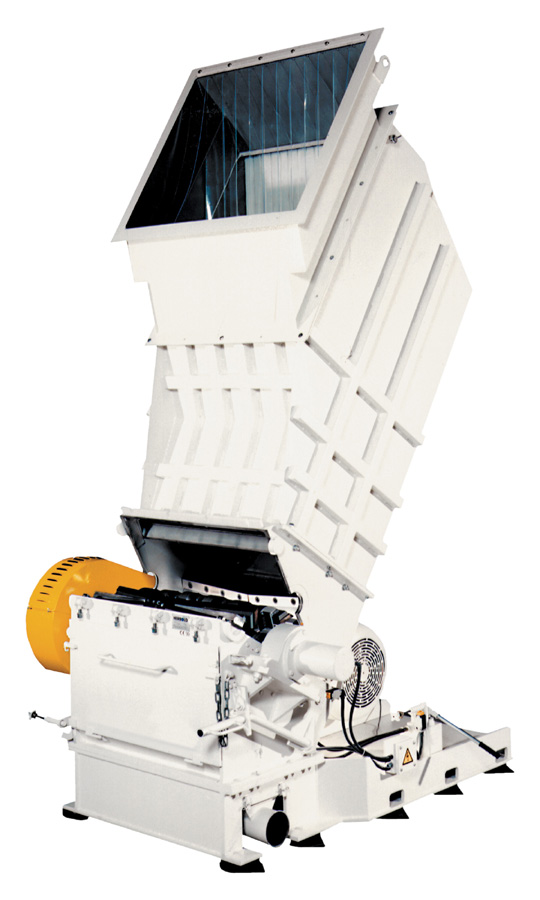

Granulator LM

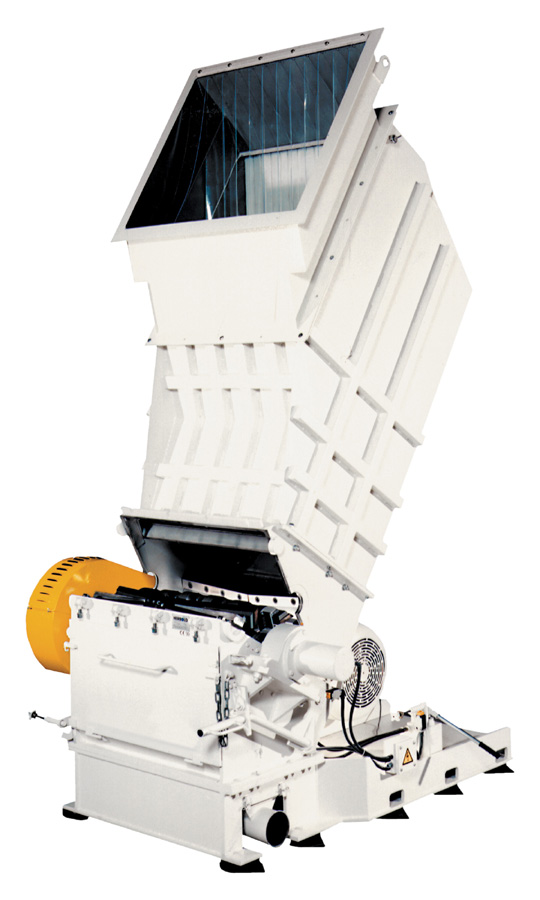

NEUE HERBOLD LM series granulators are specially designed for the size reduction of voluminous, thin walled materials.

NEUE HERBOLD LM series granulators are specially designed for the size reduction of voluminous, thin walled materials.

LM series granulators are designed with rotor and stator knives that are counter angled to each other producing a true scissors type cutting action. This design results in a cleaner more uniform granulate and reduced heat build up in the granulate. Double angle cut also reduces noise emissions and energy consumption.

Continue reading…

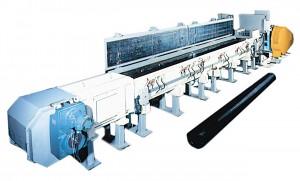

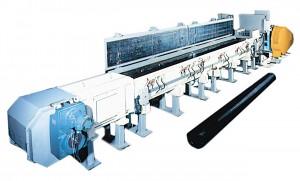

Granulator SR-LP

NEUE HERBOLD SR + LP series granulators are designed and manufactured for the size reduction of full length profiles and pipes eliminating the need to pre-cut the material into shorter lengths.

NEUE HERBOLD SR + LP series granulators are designed and manufactured for the size reduction of full length profiles and pipes eliminating the need to pre-cut the material into shorter lengths.

Continue reading…

Hammer Mills

NEUE HERBOLD HM series hammer mills offer flexibility in their application range.

NEUE HERBOLD HM series hammer mills offer flexibility in their application range.

Through the installation of material oriented rotor milling hammers tools various types of brittle plastics such as electronic scrap, wood scrap, and organic insulation material.

Continue reading…

Mobile size reduction and recycling plant

NEUE HERBOLD offers fully mobile systems designed for specific applications (size-reduction, washing, classification, separation and drying).

NEUE HERBOLD offers fully mobile systems designed for specific applications (size-reduction, washing, classification, separation and drying).

Individual units required for the task are connected with each other; the plant size and the choice of units ensuring unlimited mobility eg. the complete plant can be housed in a container or on a truck.

Continue reading…

Available rotor types for our Granulators

Because not every rotor is ideally suited for every type of feed material NEUE HERBOLD offers a variety of rotors for different applications. This makes it possible for us to meet the particular requirements of our customers.

The following list shows a summary of the design and main features of the rotors. The complete type number (eg. SM 600/1000-S5-3) of our machines gives information about the rotor design and the number of rows of cutters.

Continue reading…

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.

NEUE HERBOLD SX series granulators are specially designed for extremely high output applications.